Research on Calculation of Defect Area of Building Exterior Windows Based on Infrared Image Processing Technology

-

摘要: 将红外热成像与图像处理技术结合应用于建筑外窗缺陷的检测,提出一种外窗缺陷检测和面积计算方法。通过外窗缺陷检测实验,利用压差法进行外窗空气渗透检测,求出渗透的缺陷面积。将红外热成像仪采集的外窗红外图像进行图像的预处理、外窗缺陷的检测以及检测后的面积计算,并建立外窗缺陷红外图像检测模型。结果表明:利用加权平均法进行灰度化处理,中值滤波进行降噪处理、图像锐化和直方图均衡化进行图像增强处理,处理效果明显,可作为外窗红外图像的预处理方式;Roberts算法对预处理后外窗红外图像的检测与实验值差异最小,检测信息更接近实际缺陷位置;将处理方法和检测模型与建筑整体气密性检测结合,能够在现场对外窗气密性能等级进行初步判定。Abstract: A method for defect detection and area calculation of exterior windows of buildings is proposed by combining infrared thermal imaging technology and image processing technology. Using equipment for detection of building exterior window defects, the differential-pressure method was utilized to detect the air penetration of an exterior window, and the defective area of the air penetration of this window was calculated. Infrared images of the exterior window of the building collected by an infrared thermal imager were subjected to image preprocessing, exterior window defect detection, and area calculation after inspection. Then, an infrared-image detection model of exterior window defects was established. The results show that preprocessing can make use of the weighted average method for grayscale processing, the median filter for noise reduction, image sharpening, and histogram equalization for image enhancement processing. The outcome of the aforementioned approaches is evident. The detection of the pretreatment infrared image, which is obtained using the Roberts algorithm, minimizes the difference between the test and experimental values. This makes the detection information closer to the actual position of the defect. A primary assessment of the airtightness performance level of exterior windows can be achieved by comparing the results provided by the proposed infrared image processing technology with airtightness on-site tests.

-

0. 引言

面对全球气候环境挑战,中国正努力实现2030年前碳达峰,2060年前碳中和的目标,建筑能耗作为全球能源消耗的主要部分,随着节能减排工作的不断推进,建筑节能成为一个长期发展的目标,对于作为建筑围护结构薄弱环节的门窗而言,门窗能耗占建筑能耗很大的比例,约占外墙总能耗的50%,窗户气密性能的降低,会导致建筑能耗增加和舒适度降低的问题[1-2]。提升外窗的气密性能并减少外窗的耗能将会是提高建筑节能的重要途径之一。对于外窗的气密性能检测,目前的检测手段主要在实验室内通过静压箱法进行,将试件安装在测试设备上,测出通过试件的空气渗透量,确定其气密性能等级并出具检测报告[3]。此方法无法检出产品存在缺陷的位置,不利于不合格产品的修补。同时因实验设备和环境的制约,检测需要在实验室进行,导致在建筑外窗安装前,检测数量庞多的外窗需采用抽样检测的方法,将样品送往实验室,通过静压箱法判定是满足相应的等级。对于安装在建筑的全部外窗,抽样检测的方法无法一一判定外窗的气密性等级是否达标[4-5]。目前虽已存在对外窗气密性能进行现场检测的设备,但需要将设备安装在建筑外窗上,若对建筑中的外窗逐一进行气密性能现场检测,操作复杂且耗用大量时间,实际工程没有广泛开展,往往忽略了安装后对外窗的气密性检测。在建筑的使用过程中,因建筑沉降、环境影响、人为因素导致的外窗变形,缺陷会逐渐增多[6]。对于安装后的外窗,静压箱法已无法适用,现场检测一般利用发烟笔或用手直接感受的方式寻找缺陷位置[7-8],然而对于缺陷的准确定位相对困难。实验室检测和现场检测,无法便捷和准确地检测出外窗缺陷的位置,不仅限制了外窗在生产和施工过程中生产工艺和安装水平的提高,不利于缺陷的修补和气密性能等级的提升,影响建筑能耗和室内舒适度,也导致缺陷面积无法计算,使外窗能耗的量化分析存在困难。

红外线热成像仪利用探测器和热成像系统,接收从物质表面发出的红外线,再通过热成像仪的接收器把热信号处理转换成图像信号。人类的肉眼无法直接对物质内的温度变化做出观测与辨认,但近红外热成像技术可以协助人类在视觉上达到直接观测温度变化的目标[9-10]。对于建筑的外窗而言,普通数码图像无法识别外窗缺陷,考虑外窗缺陷处温度的异常的特点[11],选用红外热成像仪进行拍摄。同时,对于图像处理的研究已经有了丰富的成果[12-14],利用图像处理技术可以将图像中内部的边界利用计算机手段进行检测[15-16],在建筑与土木领域,已经存在利用图像处理技术对建筑轮廓提取、建筑损坏、墙体裂缝等检测的研究[17-19]。对于红外图像处理技术,国内外诸多学者利用红外热成像对建筑墙体的空鼓、损伤、渗漏等进行无损检测[20-22],通过图像中颜色变化代表的温度异常,结合图像处理技术改善红外图像质量,对目标缺陷进行识别的同时提高检测的准确性[23-24]。红外图像处理技术已经被广泛使用在建筑行业[25-26],但此项技术在建筑外窗检测中的研究较少,其高效、快速、便捷、无损等特点能够为外窗缺陷的现场检测提供便利。

本文提出一种基于红外图像处理技术的建筑外窗缺陷检测的方法,以某建筑的外窗为例,利用压差法进行建筑外窗气密性能的现场实验,并利用红外热成像仪对建筑外窗进行红外图片的采集,利用图像处理技术,对采集的图像进行一系列预处理,针对红外图像中的异常区域对外窗缺陷进行检测,并进行缺陷的面积计算和模型建立。为建筑外窗缺陷检测和外窗缺陷的面积计算提供一种新的途径,改善建筑外窗在实验室和现场检测中无法快速、准确地定位缺陷位置的问题,给外窗能耗的量化分析提供了条件。

1. 建筑外窗缺陷检测实验

建筑外窗缺陷检测,采用美国The Energy Conservatory公司DG700型测试系统进行压差法(“鼓风门”)实验,并利用瑞典FLIR SYSTEMS AB公司FLIR B200红外热成像仪对外窗进行红外图像的采集。

1.1 外窗空气渗透检测

对于外窗施工的缺陷检测,应在建筑施工过程中的门窗安装后尽早进行,以便找出外窗缺陷进行补漏工作;对运行阶段建筑而言,进行外窗缺陷检测,发现外窗缺陷并修补,可以提高室内舒适度。同时在检测过程中,测出建筑整体气密性的数值,有利于建筑整体渗漏的修补以及整体气密性能的评价[27]。

DG700型测试系统包括密封与压力调节、数据采集、TECTITE数据分析3部分。通过密封与压力调节系统对房间向内或向外鼓风,形成室内外压差,从而形成空气的流动,求出空气渗透量、房屋自然渗透率、渗漏面积等参数[28]。测试系统建立后,按照压差法实验的相应操作,进行房间整体的气密性测试;然后利用聚氯乙烯薄膜对待测外窗内部包裹,完成封堵后的气密性测试;对封堵前后实验结果统计计算出差值,得到待测外窗的渗漏面积。

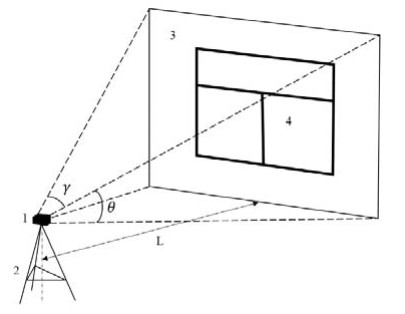

1.2 外窗红外图像的采集

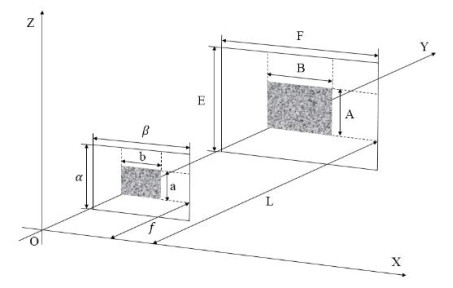

图 1为红外热成像仪采集建筑外窗图像的原理图,仪器的视场角γ×θ决定了红外热成像仪的范围,因此需要调整红外热成像仪的位置进行图像采集。将红外热成像仪通过三脚架放置在合适的位置L处,水平拍摄建筑外窗,并使建筑外窗完全显示在热成像仪屏幕内。为了减少环境因素对检测结果的影响,拍摄选择在阴天或傍晚的无风少尘的环境进行。

采集过程中在外窗空气渗透检测实验后进行。DG700型测试系统测试出的渗漏区域数值分别是在10 Pa条件下的等效渗漏面积(equivalent infiltration area, 以下简称EqLA)和4 Pa条件下的有效渗漏面积(effective infiltration area, 以下简称ELA),The Energy Conservatory公司通过计算和验证得出测试系统在10 Pa状态下的EqLA更符合建筑物气密性的物理变化结论,因此采集外窗红外图像时,设定风机的运行状态也维持室内外10 Pa的压差环境下,使红外热成像仪拍摄的外窗渗漏状态与空气渗透的实验EqLA状态保持一致,后续经外窗红外图像处理后的面积计算结果与EqLA实验值比较,确定外窗红外图像处理方式,从而实现外窗缺陷的判定和面积计算。

2. 建筑外窗红外图像处理

红外图像没有立体感觉,对肉眼而言分辨较差,利用计算机处理手段对红外图像进行处理可以解决肉眼分辨较差的问题,处理后的图片能够直观反映相关的图像信息。建筑外窗红外图像处理包括红外图像的预处理、外窗缺陷的检测以及检测后的面积计算。

2.1 红外图像预处理

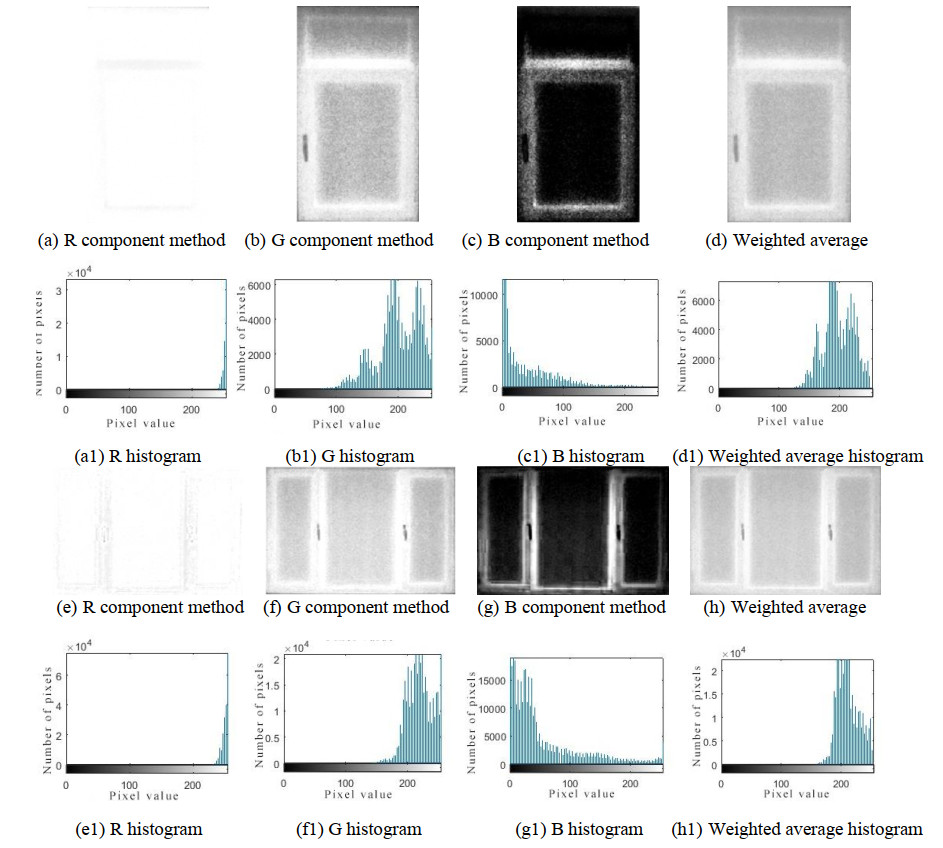

对红外图像进行灰度化处理,利用灰度值来代替红外图像的色彩值,灰度化处理往往也是处理RGB图像的首个环节。本文通过分量法与加权平均法分别对外窗红外图像进行灰度化处理,并生成能够表现灰度分布特征的灰度直方图。分量法是将图像转化为R、G、B三种灰度类型的图像,可根据3个图像的灰度值特点和图像的应用特点选择不同分量的图像。加权平均法是将R、G、B三个分量的图像进行加权取平均,获得敏感度高的灰度图像。将分量法生成的R、G、B图像直方图和加权平均法生成的图像直方图进行对比,选取四张灰度化后区分更明显的图像进行后续处理。

在红外热成像采集过程中,因采集环境中温度、湿度等影响以及热成像仪内部光学元件,会造成的图像存在噪声问题。图像中的噪声呈现出孤立的像素点、块,作为干扰信息影响图像的品质。因此在图像处理时需要对图像进行降噪处理,但在后续对外窗的红外图像进行缺陷测试时,还要保证图像中的边缘信息不能在降噪过程中被作为噪声去除。中值滤波采用领域图像中值进行全像素输出,通过噪声处理能够减少孤立的像素点,并且还可以保存领域图像中的所有细节信息,符合后续缺陷检测的处理需求,本文对外窗红外图像处理中降噪处理使用了中值滤波的处理方法。

图像进行降噪处理对图像信息产生一定的滤除影响,在后续的红外图像处理中不利于缺陷的检测识别,因此须对降噪后的图像信息进行增强处理。直方图均衡化可以达到均匀分布直方图的效果,扩大了灰度分布区域,增加了图像整体的对比度,进而使图像更加清晰。图像锐化技术可以突出图像细节,并增强图像经过滤波处理后的轮廓和边缘等信息。采取直方图均衡化以及图像锐化两个方法,对中值滤波处理后的图像进行了强化处理,通过对比处理的图像选取适合增强外窗红外图像的降噪手段。

2.2 外窗缺陷检测

边缘检测和区域分割技术利用图像中边缘处的差异对缺陷的分界线进行提取,实现相应的检测。对于建筑外窗的红外热成像图,缺陷区域与外窗正常区域的差别表现在灰度值上的差异。为更好地确定外窗缺陷检测的方式,对预处理后的图像分别进行边缘检测或阈值分割的算法,对比处理结果确定适合外窗缺陷检测的处理方法。本文选用Roberts、Sobel、Prewitt、Canny、Log算法[29]以及阈值分割法,对外窗缺陷的位置进行相应的检测。

2.3 目标面积计算

图像面积计算可通过视场角与拍摄距离计算,对于确定尺寸的矩形物体,测算物体内某部位面积可通过比例变换的方法求得。根据像素面积法原理计算红外热成像拍摄实际的缺陷面积[30-31],计算原理如图 2所示。以红外热成像仪的拍摄光心位置为原点O、热成像镜头光轴平行于Y轴,建立了红外热成像坐标系系(O-X-Y-Z)。

红外热成像图中检测缺陷区域所对应的实际缺陷面积S为:

$$ S=\frac{4 L^2 \tan \frac{\gamma}{2} \tan \theta^{m-1}}{m n} \sum_{i=0}^{n-1} \sum_{j=0}^n X(i, j) $$ (1) 式中:L为拍摄距离;γ×θ为红外热成像仪视场角;m、n分别代表二值图像的总行数和列数;i、j分别表示此像素在二值图像中的行数和列数,缺陷连通区域C中的任意的像素点的像素值表示为:

$$ X(i,j) = \left\{ {\begin{array}{*{20}{c}} {0,(i,j) \notin C} \\ {1,(i,j) \in C} \end{array}} \right. 。 $$ (2) 对于已经确定尺寸的矩形物体测算物体内部面积,通过像素坐标中二值图像的总行数m和总列数n、物体实际尺寸E、F,以及上述求得的缺陷区域像素点总和D,可得到矩形物体内部实际面积S为:

$$ S = \frac{{EFD}}{{mn}} = \frac{{EF}}{{mn}}\sum\limits_{i = 0}^{m - 1} {\sum\limits_{j = 0}^{n - 1} {X(i,j)} } $$ (3) 3. 结果与分析

3.1 外窗红外图像处理

图 3为建筑外窗灰度化处理结果,(a)~(d),(e)~(h)为两个外窗通过R分量法、G分量法、B分量法和加权平均法获取的图像,(a1)~(d1),(e1)~(h1)为(a)~(d),(e)~(h)各图像对应的灰度分度直方图,横纵坐标分别代表像素值和像素数。通过图像对比发现,R、G、B三种分量图像存在不同的特征:R的分量图(a)、(e)图像对比度很低;在灰度分布直方图中(a1)、(e1)显示像素完全聚集在某一区域。G的分量图(b)、(f)图像对比度较高,缺陷部位细节体现明显;相比而言灰度分布直方图(b1)、(f1)灰度分布较为分散、均匀。B的分量图(c)、(g)图像对比度过高,图像区分明显但图中部分细节被掩盖,不利于后续的缺陷检测;但在灰度分布直方图(c1)、(g1)中,像素分布分散。利用加权平均法处理的外窗图像,处理结果与G的分量图结果相似,(d)、(h)图像也具有较高的对比度,细节体现良好,在灰度分布直方图(d1)、(h1)中,灰度分布也较为分散。通过对外窗图像灰度化处理结果综合比较,选取加权平均法作为外窗红外图像的灰度化处理方式。

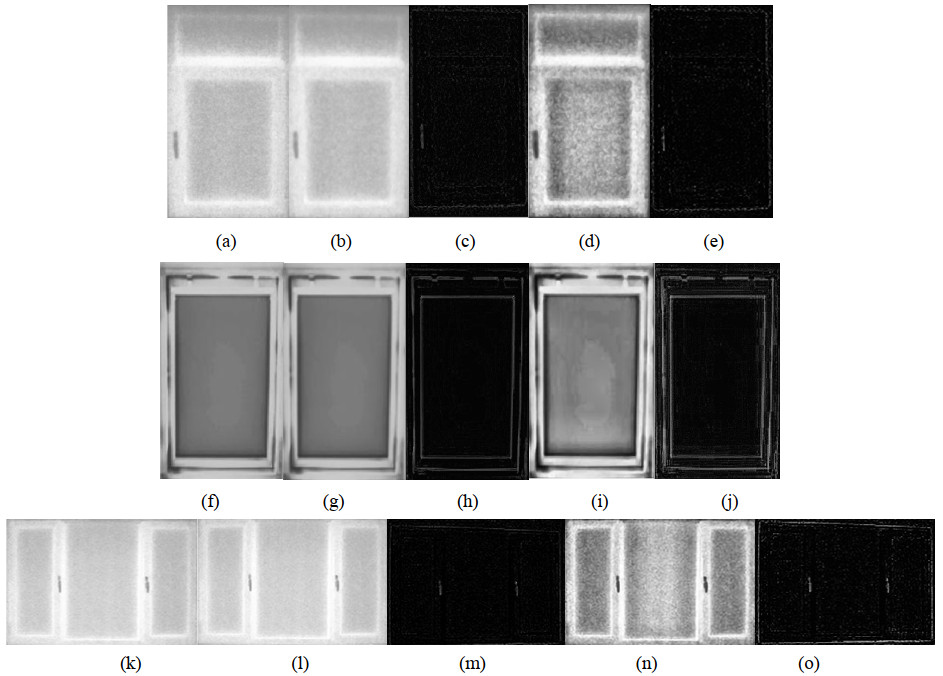

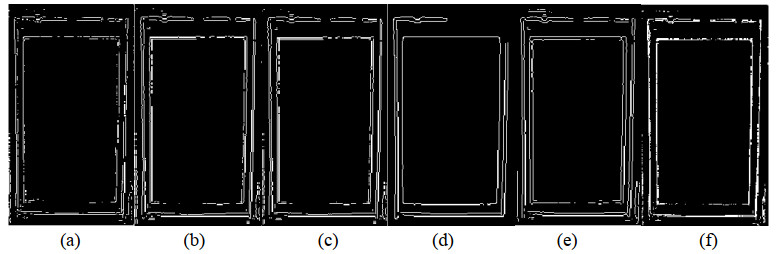

图 4是采用不同方式进行图像增强处理的结果对比。(a)、(f)、(k)是灰度化处理后的外窗图,经过中值滤波处理后的图像为(b)、(g)、(l),后对其分别进行图像锐化和直方图均衡化处理。图中(c)、(h)、(m)是利用拉普拉斯进行锐化结果,(d)、(i)、(n)为直方图均衡化结果,(e)、(j)、(o)是两种方式混合增强处理结果。从图可知,经过中值滤波处理的图像,内部细小噪声被去除的同时,窗户内部缺陷的边缘信息得到保留;经锐化处理后,图像内缺陷边缘得到锐化和增强,边界得到突出;直方图均衡化处理,图像整体对比度得到提高,但造成噪声再次产生。经图像锐化和直方图均衡化混合处理,(e)、(j)、(o)边缘较(c)、(h)、(m)更明显,增强效果更好。因此选取图像锐化和直方图均衡化混合处理作为外窗图像增强的处理方法。

![]() 图 4 图像增强结果对比(a)、(f)、(k)灰度化处理;(b)、(g)、(l)中值滤波处理;(c)、(h)、(m)拉普拉斯锐化;(d)、(i)、(n)直方图均衡化;(e)、(j)、(o)两种方式混合Figure 4. Comparison of image enhancement results: (a), (f), (k) Gray scale processing; (b), (g), (l) Median filtering; (c), (h), (m) Laplacian sharpening; (d), (i), (n) Histogram equalization; (e), (j), (o) Two methods mixed

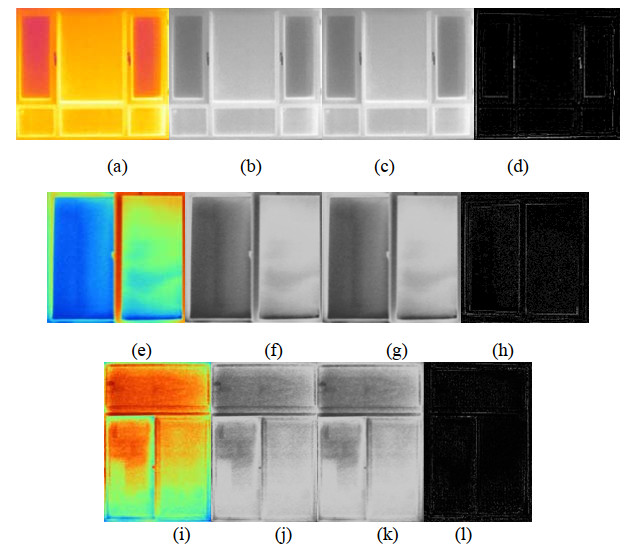

图 4 图像增强结果对比(a)、(f)、(k)灰度化处理;(b)、(g)、(l)中值滤波处理;(c)、(h)、(m)拉普拉斯锐化;(d)、(i)、(n)直方图均衡化;(e)、(j)、(o)两种方式混合Figure 4. Comparison of image enhancement results: (a), (f), (k) Gray scale processing; (b), (g), (l) Median filtering; (c), (h), (m) Laplacian sharpening; (d), (i), (n) Histogram equalization; (e), (j), (o) Two methods mixed图 5为不同外窗进行图像预处理效果,每行从左到右分别是建筑外窗原始红外图像、灰度化处理结果、中值滤波结果、图像增强结果。通过处理结果可知,采用的预处理方法对建筑外窗的红外图像预处理具有普适性。

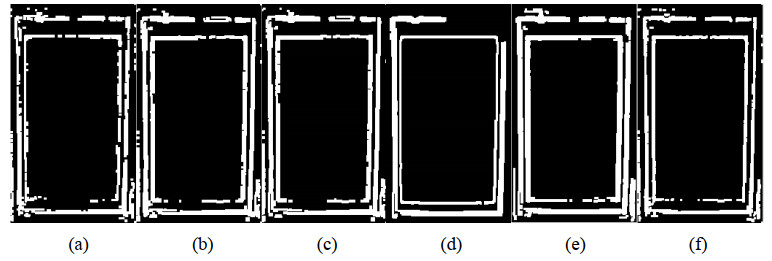

3.2 外窗缺陷识别

经预处理后对外窗红外图像进行缺陷检测识别,发现外窗缺陷存在的具体位置,实现缺陷定位。图 6是以某建筑外窗为例,分别为Roberts、Sobel、Prewitt、Canny、Log算法、阈值分割法进行检测的结果。从图可以知,外窗的缺陷从墙体和窗户中分离,缺陷轮廓明显,但轮廓内部存在空洞。图 7是经形态学处理后的结果,经形态学处理后,外窗缺陷范围内部被填充,缺陷轮廓平滑。由于各方法对目标缺陷的像素计算方式不同,导致在边缘检测中对外窗缺陷的边缘识别存在差异,同时影响缺陷面积的计算结果。因此需要对比建筑外窗空气渗透检测的实验结果,确定面积吻合较高的检测方法,并通过此方法检测和定位外窗红外图像缺陷的具体位置。

3.3 外窗缺陷面积计算

表 1为建筑外窗红外热成像图经过预处理、缺陷检测、面积计算后的结果汇总。通过外窗空气渗透检测的实验值与Roberts、Sobel、Prewitt、Canny、Log算法、阈值分割法处理后的缺陷面积的对比,不同的检测方法导致处理结果与实验值存在相应的误差。通过实验值与红外检测处理值的对比,利用Roberts进行外窗缺陷检测可以达到与实验值更为接近的结果,处理平均误差为7.23%,可认为此方法定位的外窗缺陷信息更符合实际外窗缺陷存在的位置。

表 1 外窗缺陷面积对比Table 1. Defect area comparison table of windowsWindows Value of experiment/cm2 Roberts/cm2 Sobel/cm2 Prewitt/cm2 Canny/cm2 Log/cm2 Threshold value segmentation/cm2 C0407(1) 0.90 0.96 1.39 1.39 1.70 1.62 0.92 C0407(2) 1.50 1.50 1.80 1.80 1.40 2.10 1.50 C0709(1) 3.20 3.28 4.07 3.94 3.49 5.86 3.68 C0709(2) 3.20 3.21 4.03 3.84 3.46 4.48 3.65 C0814(1) 4.30 5.19 11.32 11.07 6.58 11.61 4.70 C0814(2) 4.10 4.53 11.93 11.81 5.59 12.64 4.30 C1218(1) 11.20 11.50 14.44 14.40 15.44 7.20 11.52 C1218(2) 10.50 10.95 18.13 17.89 11.73 14.47 11.32 C1218(3) 10.30 11.03 14.22 14.02 10.89 14.76 10.43 C1218(4) 11.10 11.30 14.07 13.82 12.94 7.93 11.21 C1716(1) 9.20 9.30 11.92 11.90 9.32 4.96 9.30 C1716(2) 14.50 15.01 16.79 16.62 14.83 9.57 14.24 C2114(1) 15.80 14.86 25.42 24.88 22.93 23.33 16.87 C2114(2) 11.50 13.80 17.20 17.00 13.80 16.30 13.90 C2418(1) 22.10 24.50 30.92 30.50 36.28 26.65 25.66 C2418(2) 20.90 24.60 31.80 31.40 23.40 26.90 24.60 Error of mean - 7.23% 56.01% 53.76% 26.18% 61.60% 7.67% 除了不同的处理方式之间与实验测量值的误差对比外,单独对比各处理方式与实验值发现,利用各个方法进行外窗缺陷检测的缺陷面积普遍大于外窗缺陷检测的实验值。这与红外热成像仪的实际参数与理论参数误差对计算结果的影响有关,在进行红外检测过程中温度、湿度、风速、太阳辐射、空气质量状况等检测的环境因素会对红外辐射在传输中造成能量衰减[32],使热成像图中缺陷的状态与实际状态存在一定的差异[33],导致与实验值之间的误差;同时红外热成像检测的温度异常部位,由于温度异常的误判[34],实际不存在空气渗透,也会使处理结果大于实验值。

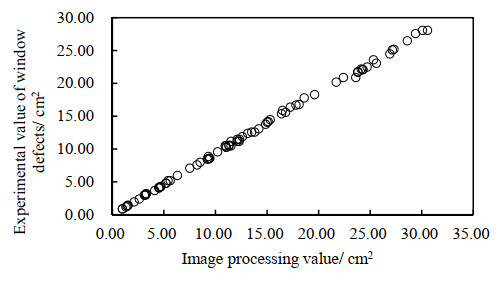

3.4 外窗缺陷红外图像检测模型

为了更好确定Roberts检测结果与实验测量值的关系,对建筑外窗的实验测量值和采集的各个外窗红外热成像处理值进行比较。图 8是80组外窗缺陷实验值和与之对应的图像处理值绘制的散点图,能够发现图像处理值与外窗缺陷实验值存在线性关系,求得线性回归模型为:y=0.920x+0.118,其中,R方统计量为0.999,拟合良好;F=81995.749,P=0,回归模型显著。外窗缺陷红外图像检测模型使平均误差降至0.76%,缩小了处理值与外窗缺陷实验值的差异,从而获得更加准确的外窗缺陷面积计算结果。

将采集的建筑外窗红外热成像图经处理后输入模型,求出建筑外窗的缺陷面积,通过建筑整体气密性能检测实验,将测出的建筑整体空气渗透量和渗透面积结合,求得对应外窗的空气渗透量,可以在现场快速对外窗气密性能等级进行简单的判定,检测其是否达到气密性能等级要求。

4. 结论

提出一种基于红外图像处理技术的建筑外窗缺陷检测和面积计算方法,对外窗红外热成像图中的缺陷进行提取和计算,与外窗空气渗透检测实验测出的外窗空气渗透面积进行对比,确定建筑外窗红外图像的处理方式,并建立外窗缺陷红外图像检测模型,实现建筑外窗缺陷的检测和面积计算。结果表明:

① 建筑外窗红外图像的预处理选用加权平均法进行灰度化处理,中值滤波进行降噪处理,图像锐化和直方图均衡化进行图像增强处理,预处理方法能够在去除外窗红外图像噪声的同时保留缺陷的边缘信息,对建筑外窗的检测具有普适性。

② 在外窗红外图像的缺陷检测中,利用Roberts算法检测缺陷面积的平均误差在7.23%,与实验值差异最小,可认为定位的外窗缺陷信息会更符合实际外窗缺陷的存在位置。通过建立外窗缺陷红外图像检测模型,将红外图像处理误差降至0.76%,能够获得更接近实验值的外窗缺陷面积计算结果。

③ 通过处理方法和检测模型,结合建筑整体气密性能检测实验,能够对外窗气密性能等级进行初步的判定。改善实际工程中,建筑外窗气密性能现场检测操作复杂的问题。

-

图 4 图像增强结果对比(a)、(f)、(k)灰度化处理;(b)、(g)、(l)中值滤波处理;(c)、(h)、(m)拉普拉斯锐化;(d)、(i)、(n)直方图均衡化;(e)、(j)、(o)两种方式混合

Figure 4. Comparison of image enhancement results: (a), (f), (k) Gray scale processing; (b), (g), (l) Median filtering; (c), (h), (m) Laplacian sharpening; (d), (i), (n) Histogram equalization; (e), (j), (o) Two methods mixed

表 1 外窗缺陷面积对比

Table 1 Defect area comparison table of windows

Windows Value of experiment/cm2 Roberts/cm2 Sobel/cm2 Prewitt/cm2 Canny/cm2 Log/cm2 Threshold value segmentation/cm2 C0407(1) 0.90 0.96 1.39 1.39 1.70 1.62 0.92 C0407(2) 1.50 1.50 1.80 1.80 1.40 2.10 1.50 C0709(1) 3.20 3.28 4.07 3.94 3.49 5.86 3.68 C0709(2) 3.20 3.21 4.03 3.84 3.46 4.48 3.65 C0814(1) 4.30 5.19 11.32 11.07 6.58 11.61 4.70 C0814(2) 4.10 4.53 11.93 11.81 5.59 12.64 4.30 C1218(1) 11.20 11.50 14.44 14.40 15.44 7.20 11.52 C1218(2) 10.50 10.95 18.13 17.89 11.73 14.47 11.32 C1218(3) 10.30 11.03 14.22 14.02 10.89 14.76 10.43 C1218(4) 11.10 11.30 14.07 13.82 12.94 7.93 11.21 C1716(1) 9.20 9.30 11.92 11.90 9.32 4.96 9.30 C1716(2) 14.50 15.01 16.79 16.62 14.83 9.57 14.24 C2114(1) 15.80 14.86 25.42 24.88 22.93 23.33 16.87 C2114(2) 11.50 13.80 17.20 17.00 13.80 16.30 13.90 C2418(1) 22.10 24.50 30.92 30.50 36.28 26.65 25.66 C2418(2) 20.90 24.60 31.80 31.40 23.40 26.90 24.60 Error of mean - 7.23% 56.01% 53.76% 26.18% 61.60% 7.67% -

[1] Mathur U, Damle R. Impact of air infiltration rate on the thermal transmittance value of building envelope[J]. Journal of Building Engineering, 2021, 40: 102302. DOI: 10.1016/j.jobe.2021.102302

[2] Lai Y, Ridley I, Brimblecombe P. Blower-door estimates of PM 2.5 deposition rates and penetration factors in an idealized room[J]. Indoor and Built Environment, 2022, 31(8): 2064-2082. DOI: 10.1177/1420326X20944427

[3] 中国建筑科学研究院有限公司. 建筑外门窗气密、水密、抗风压性能检测方法: GB/T 7106-2019[S]. 国家市场监督管理总局, 国家标准化管理委员会, 2019. China Academy of Building Research, Test methods of air permeability, water tightness, wind load resistance performance for building external windows and doors: GB/T 7106-2019[S]. State Administration for Market Regulation; Standardization Administration, 2019.

[4] 张小愉. 建筑门窗三性检测方法探究[J]. 中国建材科技, 2019, 28(6): 12-13. https://www.cnki.com.cn/Article/CJFDTOTAL-JCKJ201906006.htm ZHANG Xiaoyu. Exploration on three-character detection method of architectural doors and windows [J]. China Building Materials Science & Technology, 2019, 28(6): 12-13. https://www.cnki.com.cn/Article/CJFDTOTAL-JCKJ201906006.htm

[5] 张浚泉. 建筑门窗工程质量检测探讨[J]. 门窗, 2017(2): 23-24. https://www.cnki.com.cn/Article/CJFDTOTAL-MENC201803010.htm ZHANG Junquan. Discussion on quality inspection of building door and window engineering[J]. Doors & Windows, 2017(2): 23-24. https://www.cnki.com.cn/Article/CJFDTOTAL-MENC201803010.htm

[6] Figuli L, Papan D, Papánová Z, et al. Experimental mechanical analysis of traditional in-service glass windows subjected to dynamic tests and hard body impact[J]. Smart Structures and Systems, 2021, 27(2): 365-378.

[7] JI Y, Duanmu L. Airtightness field tests of residential buildings in Dalian, China[J]. Building and Environment, 2017, 119(7): 20-30. https://www.sciencedirect.com/science/article/pii/S0360132317301610

[8] Barreira E, Almeida R M S F, Moreira M. An infrared thermography passive approach to assess the effect of leakage points in buildings[J]. Energy & Buildings, 2017, 140(4): 224-235. https://www.sciencedirect.com/science/article/pii/S0378778817304206

[9] Freitas S S D, Freitas V P D, Barreira E. Detection of fade plaster detachments using infrared thermography – a nondestructive technique[J]. Construction & Building Materials, 2014, 70(11): 80-87.

[10] Ibarra-Castanedo C, Sfarra S, Klein M, et al. Solar loading thermography: time-lapsed thermographic survey and advanced thermographic signal processing for the inspection of civil engineering and cultural heritage structures[J]. Infrared Physics & Technology, 2017, 82: 56-74. https://www.sciencedirect.com/science/article/pii/S135044951630620X

[11] Mahmoodzadeh M, Gretka V, Wong S, et al. Evaluating patterns of building envelope air leakage with infrared thermography[J]. Energies, 2020, 13(14): 3545. DOI: 10.3390/en13143545

[12] CHEN Y F, SANG N. Attention-based hierarchical fusion of visible and infrared images[J]. Optik, 2015, 126(23): 4243-4248. DOI: 10.1016/j.ijleo.2015.08.120

[13] Lourenço Tomás, Matias Luís, Faria P. Anomalies detection in adhesive wall tiling systems by infrared thermography[J]. Construction and Building Materials, 2017, 148: 419-428. DOI: 10.1016/j.conbuildmat.2017.05.052

[14] Hiasa S H, Birgul R, Catbas N, et al. A data processing methodology for infrared thermography images of concrete bridges[J]. Computers & Structures, 2017, 190(10): 205-218. https://www.sciencedirect.com/science/article/pii/S0045794916312238

[15] Omar T, Nehdi M L, Zayed T. Infrared thermography model for automated detection of delamination in RC bridge decks[J]. Construction & Building Materials, 2018, 168: 313-327. DOI: 10.12096/j.2096-4528.pgt.2018.048

[16] LV C, WANG K, GU G, et al. Accurate full-edge detection and depth measurement of internal defects using digital speckle pattern interferometry[J]. NDT & E International, 2019, 102(3): 1-8. https://www.sciencedirect.com/science/article/pii/S0963869518302445

[17] Mohan A, Poobal S. Crack detection using image processing: A critical review and analysis[J]. Alexandria Engineering Journal, 2017: 787-798. https://www.sciencedirect.com/science/article/pii/S1110016817300236

[18] HAN Q, YIN Q, ZHENG X, et al. Remote sensing image building detection method based on mask R-CNN[J]. Complex & Intelligent Systems, 2022, 8(1): 1847-1835.

[19] Gehri N, J Mata-Falcón, Kaufmann W. Automated crack detection and measurement based on digital image correlation[J]. Construction and Building Materials, 2020, 256: 119383. DOI: 10.1016/j.conbuildmat.2020.119383

[20] Thusyanthan I, Blower T, Cleverly W. Innovative uses of thermal imaging in civil engineering[J]. Proceedings of the Institution of Civil Engineers, 2017, 170(CE2): 81-87. DOI: 10.1680/jcien.16.00014

[21] Ostańska Anna. Thermal imaging for detection of defects in envelopes of buildings in use: qualitative and quantitative analysis of building energy performance[J]. Periodica Polytechnica Civil Engineering, 2018, 62(4): 939-946.

[22] PAN N H, Tsai C H, CHEN K Y, et al. Enhancement of external wall decoration material for the building in safety inspection method[J]. Journal of Civil Engineering and Management, 2020, 26: 216-226.

[23] JIANG M. Edge enhancement and noise suppression for infrared image based on feature analysis[J]. Infrared Physics & Technology, 2018, 91: 142-152. https://www.sciencedirect.com/science/article/pii/S1350449517308617

[24] Kim C, Choi J S, Jang H, et al. Automatic detection of linear thermal bridges from infrared thermal images using neural network[J]. Applied Sciences, 2021, 11(3): 931.

[25] CHEN L, WANG Y, JIA S, et al. Development of panoramic infrared images for surface temperature analysis of buildings and infrastructures[J]. Energy and Buildings, 2020, 232(1): 110660.

[26] D Antón, Amaro-Mellado J L. Engineering graphics for thermal assessment: 3D thermal data visualisation based on infrared thermography, GIS and 3D point cloud processing software[J]. Symmetry, 2021, 13(2): 335.

[27] Mun J, Lee J, Kim M. Estimation of infiltration rate (ACH Natural) using blower door test and simulation[J]. Energies, 2021, 14(4): 912.

[28] LI X, ZHOU W, LIN D. Research on air infiltration predictive models for residential building at different pressure[J]. Building Simulation, 2020: 1-12.

[29] DI Yue, LI Meiyan, QIAO Tong, et al. Edge detection and mathematic fitting for corneal surface with Matlab software[J]. International Journal of Ophthalmology, 2017, 10(3): 336-342. http://www.ijo.cn/gjyken/ch/reader/view_abstract.aspx?file_no=20170302&flag=1

[30] Thenkabail P S, Biradar R M, Noojipady P, et al. Sub-pixel area calculation methods for estimating irrigated areas[J]. Sensors, 2007, 7(11): 2519. https://www.mdpi.com/1424-8220/7/11/2519

[31] 李峰, 周雷, 苗刚中. 基于单目视觉的目标测距方法[J]. 中国科学技术大学学报, 2012, 42: 93-98. https://www.cnki.com.cn/Article/CJFDTOTAL-WJFZ202102016.htm LI Feng, ZHOU Lei, MIAO Gangzhong. Target ranging method based on monocular vision[J]. Journal of University of Science and Technology of China, 2012, 42: 93-98. https://www.cnki.com.cn/Article/CJFDTOTAL-WJFZ202102016.htm

[32] 杨玉忠, 李丽梅, 陈刚, 等. 利用红外热像仪测试窗洞口热工缺陷的研究[J]. 建筑科学, 2016, 32(8): 111-114. https://www.cnki.com.cn/Article/CJFDTOTAL-JZKX201608019.htm YANG Yuzhong, LI Limei, CHEN Gang, et al. Study on the thermodynamic disfigurement testing for window opening by infrared thermography[J]. Building Science, 2016, 32(8): 111-114. https://www.cnki.com.cn/Article/CJFDTOTAL-JZKX201608019.htm

[33] 冯力强, 王欢祥, 晏大玮, 等. 红外热像法检测建筑外墙饰面层内部缺陷试验研究[J]. 土木工程学报, 2014, 47(6): 51-56. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201406010.htm FENG Liqiang, WANG Huanxiang, YAN Dawei, et al. Experimental study on internal defects detection of exterior wall finish coat by infrared thermography[J]. China Civil Engineering Journal, 2014, 47(6): 51-56. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201406010.htm

[34] 田鹏飞, 周骥平, 朱兴龙, 等. 基于红外热成像的气密性检测技术探讨[J]. 扬州大学学报(自然科学版), 2013, 16(2): 45-48. https://www.cnki.com.cn/Article/CJFDTOTAL-YZDZ201302012.htm TIAN Pengfei, ZHOU Jiping, ZHU Xinglong, et al. Research on air tightness detection based on infrared thermal imaging[J]. Journal of Yangzhou University(Natural Science Edition), 2013, 16(2): 45-48. https://www.cnki.com.cn/Article/CJFDTOTAL-YZDZ201302012.htm

-

期刊类型引用(5)

1. 余超,王利昭,马延会,王一波,季昌国,王智春,张鹏鲲. 相控阵超声检测图谱缺陷面积精准计算软件设计. 无损探伤. 2024(03): 17-20 .  百度学术

百度学术

2. 李环宇,冯国会,刘馨,蒲毅,王涵. 基于红外热成像的围护结构热工性能定量检测方法研究进展. 太阳能学报. 2024(07): 427-437 .  百度学术

百度学术

3. 付相球,张喜臣,王晓军,戴红亮,刘宁,赵倩. 建筑外门窗气密性能研究综述. 建筑科学. 2024(12): 107-115+290 .  百度学术

百度学术

4. 张玲玲,任攀攀,许廒,张继冉,丁立斌,安朝封,吴松. 基于红外图像处理的建筑外窗气密性能现场检测. 红外技术. 2023(04): 410-416 .  本站查看

本站查看

5. 张玲玲,张继冉,许廒,任攀攀,丁立斌. 基于红外图像处理的建筑外窗缺陷能耗分析研究. 红外技术. 2023(09): 996-1004 .  本站查看

本站查看

其他类型引用(6)

下载:

下载: