Infrared Thermography-based Void Detection Technology for Concrete-filled Steel Tubes

-

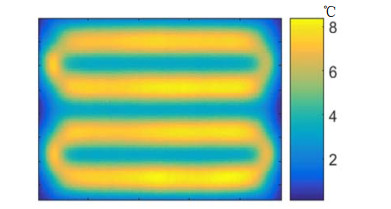

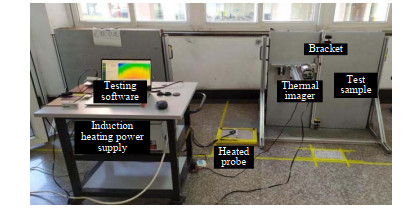

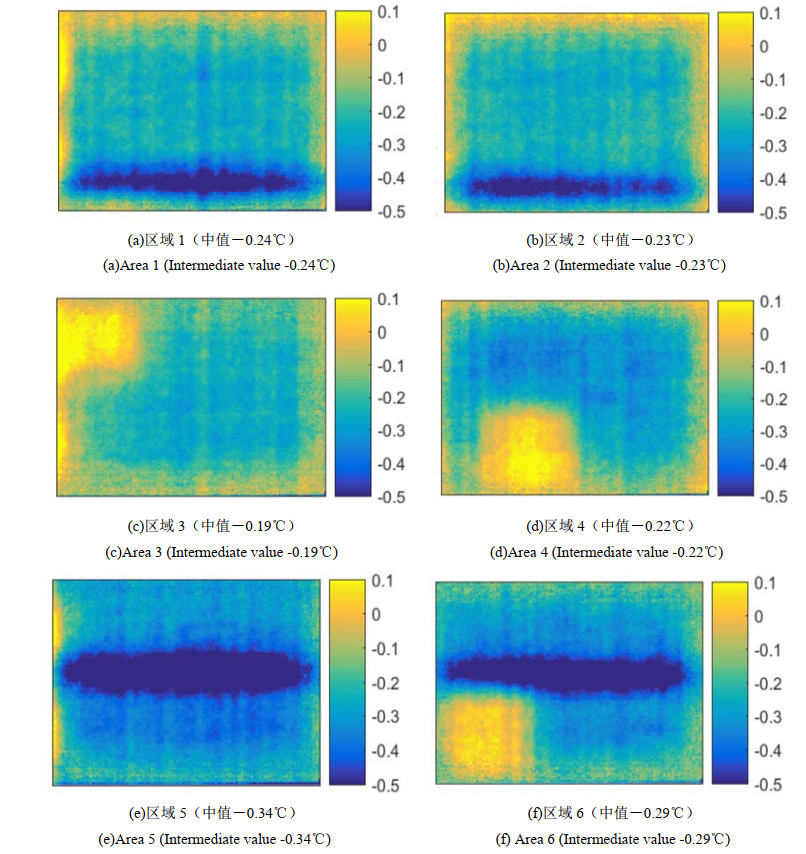

摘要: 钢管混凝土结构因受施工工艺、混凝土收缩、超负荷承载等因素而产生脱空缺陷,使结构的承载能力下降。本文利用主动热成像技术对钢管混凝土的脱空缺陷进行了研究,并针对当前热成像脱空检测技术存在检测深度小,处理算法呈现效果不佳,无法定量检测,检测效率低等问题,提出了设计专用感应加热电源和线盘提高检测深度,热源反演算法消除加热非均匀性干扰,建立无缺陷仿真模型预测钢管混凝土表面的温度分布,取同一时刻的实验数据和仿真预测数据作差来提取脱空缺陷特征,以及检测参数优化实现定量检测的解决方法。通过多次重复实验表明,可检出壁厚为20 mm钢管混凝土内的脱空缺陷,并能确定缺陷形状和大小,有效提高了检测深度和检测效率。Abstract: The concrete-filled steel tube structure has void defects owing to factors such as construction technology, concrete shrinkage, and overload bearing, which reduce the load-bearing capacity of the structure. Furthermore, the current thermal imaging based void detection technology has a small detection depth, poor processing algorithm rendering effect, inability to detect quantitatively, and low detection efficiency. In this study, an active thermal imaging technology was used to study the void defects of concrete-filled steel tubes. A special induction heating power supply and heating probe are designed to increase the detection depth, and a heat source inversion algorithm eliminates the heating non-uniformity interference. In addition, a defect-free simulation model is established to predict the temperature distribution of the concrete-filled steel tube surface. Moreover, the difference between the experimental data and the simulation prediction data was obtained to extract the characteristics of the void defect and optimize the detection parameters to realize a quantitative detection solution. Through repeated experiments, it was shown that void defects in concrete-filled steel tubes with a wall thickness of 20mm can be detected, and the shape and size of the defects can be determined, which effectively improves the inspection depth and efficiency.

-

-

表 1 材料的物性参数

Table 1 Material parameters

Material Thermal conductivity/

W·m-1·K-1Specific heat

capacity/

J·kg-1·K-1Density/

kg·m-3Steel 49.8 465 7840 Concrete(c30) 1.28 970 2410 Air 0.0259 1005 1.205 -

[1] 张西辰, 宋晓冰. 钢板混凝土(SC)组合结构的发展与研究现状[J]. 四川建筑科学研究, 2015, 41(1): 26-30. DOI: 10.3969/j.issn.1008-1933.2015.01.006 ZHANG Xichen, SONG Xiaobing. Research and application of steel concrete composite structure[J]. Sichuan Building Science, 2015, 41(1): 26-30. DOI: 10.3969/j.issn.1008-1933.2015.01.006

[2] 安东. 双钢板混凝土组合剪力墙发展及其承载力研究现状[J]. 城市建设理论研究, 2019, 302(20): 53-53. https://www.cnki.com.cn/Article/CJFDTOTAL-CSJL201920045.htm AN Dong. Development and bearing capacity of double steel plate concrete composite shear wall[J]. Theoretical Research in Urban Construction, 2019, 302(20): 53-53. https://www.cnki.com.cn/Article/CJFDTOTAL-CSJL201920045.htm

[3] 陈志华, 姜玉挺, 张晓萌, 等. 钢管束组合剪力墙恢复力模型研究[J]. 地震工程与工程振动, 2017, 37(1): 115-122. https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC201701015.htm CHEN Zhihua, JIANG Yuting, ZHANG Xiaomeng, et al. Research on resilience model of steel tube bundle composite shear wall[J]. Earthquake Engineering and Engineering Dynamics, 2017, 37(1): 115-122. https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC201701015.htm

[4] 周云, 裴熠麟, 刘蒙. 基于非接触式麦克风冲击共振测试的钢-混组合结构界面脱空损伤识别方法研究[J]. 地震工程与工程振动, 2020, 40(1): 67-79. https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC202001008.htm ZHOU Yun, PEI Yilin, LIU Meng. Non-contact diagnosis for interface debonding of steel-concrete composited structure by using impact resonance test with microphone[J]. Earthquake Engineering and Engineering Dynamics, 2020, 40(1): 67-79. https://www.cnki.com.cn/Article/CJFDTOTAL-DGGC202001008.htm

[5] 叶勇, 李威, 陈锦阳. 考虑脱空的方钢管混凝土短柱轴压性能有限元分析[J]. 建筑结构学报, 2015, 36(S1): 324-329. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB2015S1050.htm YE Yong, LI Wei, CHEN Jinyang. FEA on compressive behavior of square CFST short columns with circumferential gap between concrete and tube[J]. Journal of Building Structures, 2015, 36(S1): 324-329. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB2015S1050.htm

[6] 史新伟. 超声波法检测钢管混凝土脱空量及快速修补技术研究[D]. 郑州: 郑州大学, 2009. SHI Xinwei. Research on the void size in concrete-filled steel tube by ultrasonic wave method and the rapid repairing techniques[D]. Zhengzhou: Zhengzhou University, 2009.

[7] 段师剑, 王远传, 赵勇. 超声法检测钢管混凝土缺陷的分析与探讨[J]. 无损检测, 2018, 40(12): 74-78. DOI: 10.11973/wsjc201812015 DUAN Shijian, WANG Yuanchuan, ZHAO Yong. Analysis and discussion of steel pipe-encased concrete defects by ultrasonic inspection[J]. Nondestructive Testing, 2018, 40(12): 74-78. DOI: 10.11973/wsjc201812015

[8] 岳文军, 杨国强, 王栋, 等. 钢管混凝土脱粘的超声波检测模型试验[J]. 施工技术, 2016, 45(23): 151-155. https://www.cnki.com.cn/Article/CJFDTOTAL-SGJS201623039.htm YUE Wenjun, YANG Guoqiang, WANG Dong, et al. Test and control technology and application of steel tube concrete arch bridge[J]. Construction Technology, 2016, 45(23): 151-155. https://www.cnki.com.cn/Article/CJFDTOTAL-SGJS201623039.htm

[9] 晏国顺, 张富家, 王旭明. 中子无损检测法在泸定水电站蜗壳脱空检测中的应用[J]. 水力发电, 2011, 37(5): 83-84, 88. https://www.cnki.com.cn/Article/CJFDTOTAL-SLFD201105032.htm YAN Guoshun, ZHANG Fujia, WANG Xuming. Application of neutron non-destructive testing method in the void detection of spiral case in Luding Hydropower Station[J]. Water Power, 2011, 37(5): 83-84, 88. https://www.cnki.com.cn/Article/CJFDTOTAL-SLFD201105032.htm

[10] 张辉, 刘国庆, 刘枨, 等. 水电站钢衬混凝土结构脱空缺陷定量检测应用研究[J]. 同位素, 2017, 30(3): 194-199. https://www.cnki.com.cn/Article/CJFDTOTAL-TWSZ201703007.htm ZHANG Hui, LIU Guoqing, LIU Cheng, et al. Study on Application of quantitative detecting of inner cavity defect of concrete under steel plate lining of hydro-power plant[J]. Journal of Isotopes, 2017, 30(3): 194-199. https://www.cnki.com.cn/Article/CJFDTOTAL-TWSZ201703007.htm

[11] 杨金. 基于HHT的钢管混凝土缺陷特征提取研究与FPGA实现[D]. 湘潭: 湖南科技大学, 2016. YANG Jin. Feature extraction from concrete-filled steel tube using HHT and FPGA implementation[D]. Xiangtan: Hunan University of Science and Technology, 2016.

[12] Zimnoch M, Oliferuk W, Maj M. Estimation of defect depth in steel plate using lock-in IR thermography[J]. Geological Data Processing, 2010, 17: 156-159. http://yadda.icm.edu.pl/baztech/download/import/contents/BPB2-0048-0019-httpwww_actawm_pb_edu_plvol4no4zimnocholiferukmaj2009070.pdf

[13] Cotic P, Kolaric D, Bosiljkov V B, et al. Determination of the applicability and limits of void and delamination detection in concrete structures using infrared thermography[J]. NDT & E International, 2015, 74(9): 87-93. http://smartsearch.nstl.gov.cn/paper_detail.html?id=7df88ae15f98281a4b18c7fea5110e29

[14] 胡爽. 基于红外热像技术的钢管混凝土密实度缺陷检测探究[D]. 重庆: 重庆大学, 2016. HU Shuang, The research and detection on the density defects of the concrete-filled steel tubes based on the infrared thermal imaging technology[D]. Chongqing: Chongqing University, 2016.

[15] Matovu M J, Farhidzadeh A, Salamone S. Damage assessment of steel-plate concrete composite walls by using infrared thermography: a preliminary study[J]. Journal of Civil Structural Health Monitoring, 2016, 6(2): 303-313. DOI: 10.1007/s13349-016-0169-4

[16] 王军文, 马少宁, 刘志勇, 等. 钢管混凝土脱空无损检测方法试验研究[J]. 石家庄铁道大学学报: 自然科学版, 2021, 34(2): 38-45. https://www.cnki.com.cn/Article/CJFDTOTAL-SJZT202102007.htm WANG Junwen, MA Shaoning, LIU Zhiyong, et al. Experimental study on non-destructive testing methods of voids in concrete filled steel tube[J]. Journal of Shijiazhuang Tiedao University: Natural Science Edition, 2021, 34(2): 38-45. https://www.cnki.com.cn/Article/CJFDTOTAL-SJZT202102007.htm

[17] 张顺. 基于涡流热成像的钢管混凝土拱桥脱空检测试验研究[D]. 重庆: 重庆交通大学, 2019. ZHANG Shun. Research on void detection of concrete filled steel tubular arch bridge based on eddy current thermal imaging[D]. Chongqing: Chongqing Jiaotong University, 2019.

[18] 陈禾, 秦迎, 陈劲, 等. 基于红外热成像法和超声波法的钢管混凝土无损检测技术试验研究[J]. 建筑结构, 2020, 50(S1): 890-895. https://www.cnki.com.cn/Article/CJFDTOTAL-JCJG2020S1174.htm CHEN He, QIN Ying, CHEN Jin, et al. Experimental research on the non-destructive detecting technique on concrete-filled steel tube based on infrared thermal imaging method and ultrasonic method[J]. Building Structure, 2020, 50(S1): 890-895. https://www.cnki.com.cn/Article/CJFDTOTAL-JCJG2020S1174.htm

[19] 李晓希. 多层异种金属粘接结构内部缺陷热成像无损检测研究[D]. 成都: 电子科技大学, 2018. LI Xiaoxi. A research of thermography NDT for inner defect in multi-layer metal-to-metal bonded structure[D]. Chengdu: University of Electronic Science and Technology of China, 2018.

[20] 张绩松, 王晓娜, 侯德鑫, 等. 基于激光热成像的局部导热系数测试[J]. 激光与红外, 2020, 50(12): 1426-1432. https://www.cnki.com.cn/Article/CJFDTOTAL-JGHW202012003.htm ZHANG Jisong, WANG Xiaona, HOU Dexin, et al. Local thermal conductivity measurement based on laser thermography[J]. Laser & Infrared, 2020, 50(12): 1426-1432. https://www.cnki.com.cn/Article/CJFDTOTAL-JGHW202012003.htm

下载:

下载: