Detection and Recognition of Metal Fatigue Cracks by Bi-LSTM Based on Eddy Current Pulsed Thermography

-

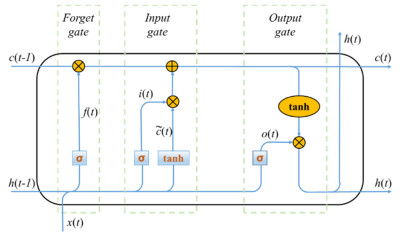

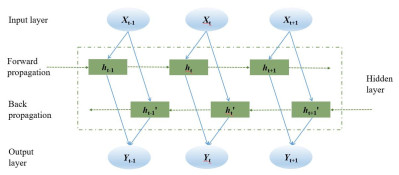

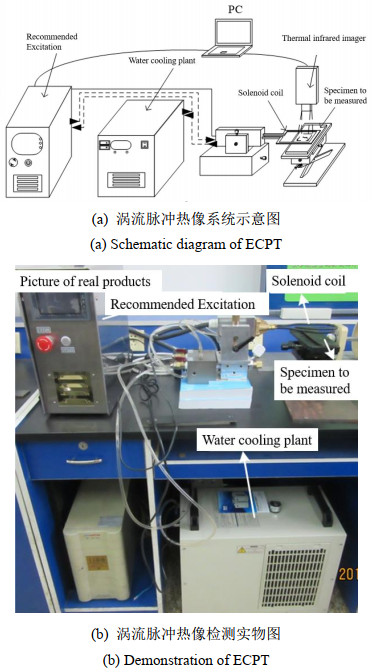

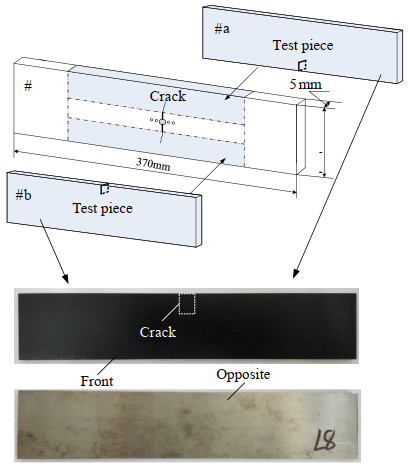

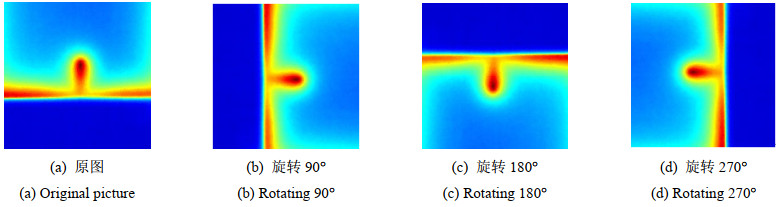

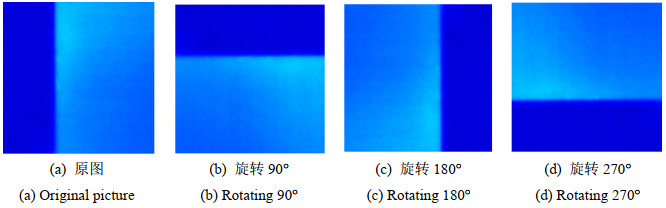

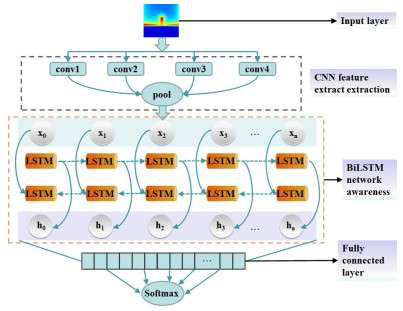

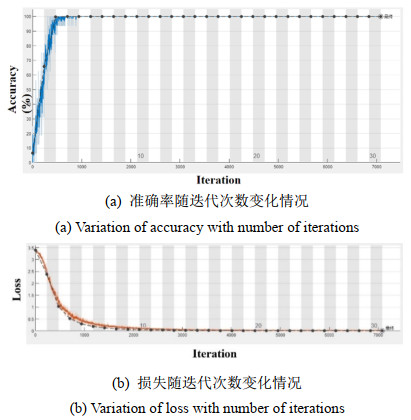

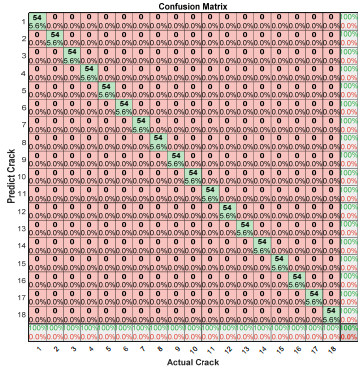

摘要: 涡流脉冲热像(Eddy current pulsed thermography,ECPT)技术是一种新型的无损检测方法,广泛应用于金属材料结构的检测,但该技术常依赖人工经验提取特征进行裂纹检测与识别,自动化和智能性化程度不足。结合涡流脉冲热像技术以及循环神经网络(Recurrent Neural Network,RNN)的特性,提出一种基于双向长短期记忆网络(Bidirectional Long Short-Term Memory Network,Bi-LSTM)金属疲劳裂纹涡流脉冲热像分类识别方法。实验通过涡流加热装置对被测金属试件进行感应加热,使用红外热像采集装置对金属平板试件进行实时的数据采集,获得图像序列并制作数据集。运用设计的Bi-LSTM模型增强特征向量中的时序信息,对不同尺寸裂纹的热图像进行训练并测试。实验分析表明,Bi-LSTM网络可有效应用于金属疲劳裂纹检测与识别,针对现有裂纹检测准确率可达到100%,优于传统神经网络和其他深度学习的模型,具有更高的识别精度。Abstract: Eddy current pulsed thermography is a new nondestructive testing method that is widely used in metal structure testing. However, the extraction of features for crack detection and identification relies on manual experience, and the degree of automation and intelligence is insufficient. By combining the characteristics of eddy current pulsed thermography with a recurrent neural network (RNN), a bidirectional long short-term memory (Bi-LSTM)-based eddy current pulse thermography method is proposed for metal fatigue crack classification and recognition. The Bi-LSTM model was designed to enhance the transient information in the feature vectors. In the experiments, an eddy current heating device was used to heat the tested metal specimens. A real-time dataset was created using an infrared thermal camera that collected sequences of images. The Bi-LSTM model was trained on thermal images of cracks of different sizes and tested. Experimental analyses show that the Bi-LSTM network can be effectively applied for metal fatigue crack detection and recognition, with the detection accuracy reaching 100% for the cracks used in the experiments, which is superior to that of traditional neural networks and other deep learning models.

-

0. 引言

随着科技的发展,目标的高机动性及大离轴角发射能力对防空导弹提出了更高的要求。滚转摆动式导引头采用滚转摆动两轴极坐标控制形式,外框为滚动框,内框为摆动框,视场可覆盖整个前半球,具有结构简单、重量轻、体积小、成本低等特点,因此非常适用于近程红外防空导弹。但是由于滚摆式导引头不能直接测量视线角速率,因此研究其视线角速率获取方式显得极为重要[1-2]。文献[3-4]对滚仰导引头跟踪平台进行了建模并做了仿真,文献[5-6]指出了滚仰式导引头存在奇异性的原因。文献[7]提出需要用滤波的方法得到目标视线角速度。

本文对滚摆式导引头的视线角速率进行研究,讨论了滚摆式导引头与偏仰式导引头视线角速率存在的差异,推导了角速率的提取公式,并对其做了简化,分析了简化公式的使用条件。

1. 坐标系定义

载体基座系Obxbybzb与弹体固连,原点选在外框与内框的交点。Obxb沿弹轴方向,Obyb在导弹纵向对称面内与Obxb垂直,Obzb通过右手定则确定。

滚摆导引头外框与传统的偏仰式导引头不同的是外框为滚动框,内框为摆动框,如图 1所示。外框坐标系Owxwywzw与外框固连,描述外框的运动。内框坐标系Onxnynzn与内框固连,描述内框的运动。载体基座系绕其Obxb轴旋转γn到达外框坐标系,外框系绕其轴Owzw摆动θn到达内框坐标系。在导引头稳定跟踪的条件下,可认为内框坐标系Onxn指向目标。同理,对于偏仰式导引头,如图 2所示,两个框架角分别为:kz,ky。

视线坐标系Osxsyszs原点与内框系重合,Osxs指向目标,Osys在铅垂面内与Osxs垂直,Oszs通过右手定则确定。定义视线系与惯性系的夹角为目标的高低和方位角记为qy与qz。

2. 滚摆式导引头视线角速度绕x轴旋转问题

滚摆导引头跟踪过程中,导引头通过测量目标相对于光轴的像素差,将其转化为滚动框指令与摆动框指令,驱使光轴指向目标。

对于偏仰式平台导引头,由于在内框上安装有速率陀螺,可以测量得到光轴相对于惯性空间的角速度,在导引头稳定跟踪的条件下,即可将此角速度用于制导。但滚摆导引头由于滚动框剧烈滚动,内框系与视线系存在沿视线方向的旋转,导致视线系Osys轴与内框系Onyn轴并不重合,内框系测量的角速度不能直接用于制导,下面详细分析这个问题。

定义视线系绕其纵轴旋转qr与内框系重合。设目标在空间的高低和方位角为qy与qz。此时弹体3个欧拉角为$\vartheta , \psi , \gamma $。坐标转换关系如图 3所示。

弹目相对量在惯性空间的单位矢量为:

$${\vec i_{\rm{r}}} = [\begin{array}{*{20}{c}} {\cos ({q_y})\cos ({q_z})}&{\sin ({q_y})}&{ - \cos ({q_y})\sin ({q_z})} \end{array}]$$ (1) 将其投影到弹体系下,得到:

$${\vec i_{{\rm{rb}}}} = {M_{{\rm{b}}2{\rm{e}}}}[\begin{array}{*{20}{c}} {\cos ({q_y})\cos ({q_z})}&{\sin ({q_y})}&{ - \cos ({q_y})\sin ({q_z})} \end{array}]$$ (2) 式中:${M_{{\rm{b2e}}}} = \left[ {{M_1}(\gamma ){M_3}(\vartheta ){M_2}(\psi )} \right]$

若采用滚摆式导引头,弹目相对量在弹体系也可表示为:

$${\vec i_{{\rm{rb}}}} = [{\rm{cos(}}{\theta _{\rm{n}}}{\rm{) sin(}}{r_{\rm{n}}}{\rm{)sin(}}{\theta _{\rm{n}}}{\rm{) }} - {\rm{cos(}}{r_{\rm{n}}}{\rm{)sin(}}{\theta _{\rm{n}}}{\rm{)}}]$$ (3) 其中:

$$\begin{gathered} {\theta _{\rm{n}}} = {\cos ^{ - 1}}(\overrightarrow {{i_{{\rm{rb}}}}} (1)) \\ {k_z} = {\tan ^{ - 1}}(\overrightarrow {{i_{{\rm{rb}}}}} (2), - \overrightarrow {{i_{{\rm{rb}}}}} (3)) \\ \end{gathered} $$ (4) 或:

$$\begin{gathered} {\theta _{\rm{n}}} = - {\cos ^{ - 1}}(\overrightarrow {{i_{{\rm{rb}}}}} (1)) \\ {k_z} = {\tan ^{ - 1}}( - \overrightarrow {{i_{{\rm{rb}}}}} (2), \overrightarrow {{i_{{\rm{rb}}}}} (3)) \\ \end{gathered} $$ (5) 由于弹体系到视线系的转化矩阵为:

$$\begin{gathered} {M_{{\rm{b2s}}}} = {M_3}({q_y}){M_2}({q_z}){\left[ {{M_1}(\gamma ){M_3}(\vartheta ){M_2}(\psi )} \right]^{ - 1}} \\ = {M_1}{({q_{\rm{r}}})^{ - 1}}{M_2}({\theta _{\rm{n}}}){M_1}({r_{\rm{n}}}) \\ = {M_1}{({q_{\rm{r}}})^{ - 1}}{M_3}({k_y}){M_2}({k_z}) \\ \end{gathered} $$ (6) 则易得视线系和内框系的扭角qr为:

(7) 导弹滚转角和导引头滚转框架角之和r+rn为:

(8) 若制导方式采用比例导引:

$$\dot q = \frac{{V\sin (\eta ) - {V_{\rm{t}}}\sin ({\eta _{\rm{t}}})}}{r}$$ (9) 式中:$\dot q$为弹目视线角速率;V为导弹速度;η为导弹速度前置角;Vt为目标速度;ηt为目标速度前置角;r为弹目相对距离。

当$\dot q$→0,则$\sin (\eta ) = \frac{{{V_{\rm{t}}}\sin ({\eta _{\rm{t}}})}}{V}$若V>>Vt,则η→0。故qr≈r+rn,即扭角近似等于导弹滚转角和导引头滚转框架角之和。

若采用偏仰式导引头,视线系和内框系的扭角qr为:

$$\tan {q_{\rm{r}}} = ({M_{{\rm{b2s}}}}(3, 2)/{M_{{\rm{b2s}}}}(2, 2))$$ (10) 其中:

$$\begin{align} & {{M}_{\text{b2s}}}(3,2)=\cos \!\left( \psi -{{q}_{z}} \right)\,\sin \!\left( \gamma \right)+ \\ & \sin \!\left( \psi -{{q}_{z}} \right)\,\cos \!\left( \gamma \right)\,\sin \!\left( \vartheta \right) \\ \end{align}$$ (11) $$\begin{align} & {{M}_{\text{b2s}}}(2,2)=\cos \!\left( \gamma \right)\cos \!\left( {{q}_{y}} \right)\,\cos \!\left( \vartheta \right)+ \\ & \cos \!\left( \gamma \right)\,\cos \!\left( \psi -{{q}_{z}} \right)\,\sin \!\left( {{q}_{y}} \right)\,\sin \!\left( \vartheta \right) \\ & -\sin \!\left( \psi -{{q}_{z}} \right)\,\sin \!\left( \gamma \right)\,\sin \!\left( {{q}_{y}} \right) \\ \end{align}$$ (12) 若V > > Vt,则η→0,故qr≈r。即扭角近似等于导弹滚转角。

由上述分析可知,当采用偏仰式导引头,弹体采用三通道倾斜稳定控制时,导弹滚转角很小,故导引头测量系输出的角速度可以近似认为等于视线系角速度。

但采用滚摆式导引头时,由于滚动框高速转动,导引头测量系与视线系差别很大,故不能直接用测量系的视线角速度制导。

3. 滚摆式导引头视线角速度获取方式

若滚摆导引头内框上未安装速率陀螺,只能通过码盘获得框架角,需要综合弹上惯导信息对视线角速度进行重构。

内框系测量的角速度包含3部分,一是弹体相对惯性空间的角速度,二是外框相对于弹体的角速度,三是内框相对于外框的角速度,将其都投影到内框系,即:

$$\begin{array}{l} w_{{\rm{b}}\;{\rm{o}}}^{\rm{n}} = {M_2}({\theta _{\rm{n}}}){M_1}({r_{\rm{n}}})w_{{\rm{bo}}}^{\rm{b}}\\ w_{{\rm{w}}\;{\rm{b}}}^{\rm{n}} = {M_2}({\theta _{\rm{n}}}){\left[ {{{\dot r}_{\rm{n}}}\;\;0\;\;0} \right]^{\rm{T}}}\\ w_{{\rm{n}}\;{\rm{w}}}^{\rm{n}} = {\left[ {0\;\;{{\dot \theta }_{\rm{n}}}\;\;0} \right]^{\rm{T}}} \end{array}$$ (13) 故:

$$w_{{\rm{n}}\;{\rm{o}}}^{\rm{n}} = w_{{\rm{b}}\;{\rm{o}}}^{\rm{n}} + w_{{\rm{w}}\;{\rm{b}}}^{\rm{n}} + w_{{\rm{n}}\;{\rm{w}}}^{\rm{n}}$$ (14) wnon又可用qy、qz、qr表示为:

$$ {\rm{w}}_{{\rm{no}}}^{\rm{n}} = {M_1}\left( {{q_r}} \right){\left[ {{{\dot q}_r} + {{\dot q}_z}\sin \left( {{q_y}} \right)\;\;{{\dot q}_z}\cos \left( {{q_y}} \right)\;\;{{\dot q}_y}} \right]^{\rm{T}}} $$ (15) 由于制导需要的是视线系视线角速度,即:

$$\begin{array}{l} w_{{\rm{so}}}^{\rm{s}} = {\left[ {0\;\;0\;\;{{\dot q}_y}} \right]^{\rm{T}}} + {M_3}\left( {{q_y}} \right){\left[ {0\;\;{{\dot q}_z}\;\;0} \right]^{\rm{T}}}\\ = {M^{\rm{T}}}_1\left( {{q_r}} \right)\left( {w_{{\rm{no}}}^{\rm{n}} - {{\left[ {\;{{\dot q}_r}\;\;0\;\;0} \right]}^{\rm{T}}}} \right) \end{array}$$ (16) 沿视线的旋转不影响角速度的俯仰偏航分量,故可将内框角速度按qr做逆向分解,即可用于制导。

下面讨论qr如何求取。半捷联式滚摆导引头只能获得两个框架角θn,rn,结合弹上惯导$\vartheta , \psi , \gamma $信息即可求出qr准确的值,但表达式过于复杂,不利于计算机实现,前面已经求出qr≈r+rn,下面对该式的近似精度做分析,将式(7)和式(8)重新列写如下:

$$\begin{align} & \tan {{q}_{\text{r}}}=-({{M}_{\text{b2s}}}(2,1)/{{M}_{\text{b2s}}}(3,1)) \\ & \frac{-\cos \!\left( {{q}_{y}} \right)\,\sin \!\left( \vartheta \right)+\cos \!\left( \psi -{{q}_{z}} \right)\,\cos \!\left( \vartheta \right)\,\sin \!\left( {{q}_{y}} \right)}{\sin \!\left( \psi -{{q}_{z}} \right)\,\cos \!\left( \vartheta \right)} \\ \end{align}$$ (17) $$\begin{align} & \tan (r+{{r}_{n}})=\!-({{M}_{\text{b2s}}}(1,2)/{{M}_{\text{b2s}}}(1,3)) \\ & \frac{\,\cos \!\left( \vartheta \right)\,\sin \!\left( {{q}_{y}} \right)-\cos \!\left( \psi -{{q}_{z}} \right)\,\cos \!\left( {{q}_{y}} \right)\,\sin \!\left( \vartheta \right)}{\sin \!\left( \psi -{{q}_{z}} \right)\,\,\cos \!\left( {{q}_{y}} \right)} \\ \end{align}$$ (18) 由表达式可以看出,qr与qy、qz-Ψ、qz-相关。

由图 4可以看出,当俯仰跟偏航框架角很小时,用r+rn近似qr有很高的精度。当俯仰视线角在20°以内,俯仰偏航框架角在10°以内时,误差角(r+rn)-qr不超过5°。随着框架角的绝对值增大,误差角逐渐增大。随着俯仰视线角的增大,误差角也逐渐增大。当俯仰视线角增大到40°时,误差角最大到16°左右。此时俯仰姿态角已经接近60°。因此在大部分情况下,应用上述公式近似的误差角不超过15°。

4. 仿真验证

设目标高度4500 m,速度400 m/s,交汇距离10000 m,航路捷径2000 m。导弹平均速度600 m/s,导航比k=4。仿真结果如图 5、图 6所示。

图 5中(a)为qr与r+rn之差,(b)为导弹姿态角,(c)为俯仰框架角,(d)为偏航框架角。由图可知,导弹俯仰姿态角最大为40°,俯仰框架角绝对值最大为-20°,偏航框架角最大为10°左右,误差角最大不超过6°。由图 6可知理想的视线角速度跟近似的相差无几,表明简化公式qr≈r+rn在一定条件下是适应的。

5. 结论

本文讨论了滚摆式导引头与偏仰式导引头视线角速率存在的差异,阐述了滚摆式导引头存在绕x轴角速度的原因。并给出了半捷联式滚摆导引头角速率的获取方式,推导了其简化形式,分析了简化公式使用的条件。经过数字仿真,对比了理论视线角速度和简化公式求取的视线角速度,结果表明该简化公式具有较好的近似精度,有一定的工程应用前景。

-

表 1 18类金属试件裂纹长度及其编号

Table 1 Crack length and numbering of 18 metal specimens

Serial numbers Crack length/μm 1 0 2 1707.41 3 1986.66 4 2181.48 5 3454.42 6 3474.50 7 3898.49 8 4639.50 9 4866.00 10 5263.50 11 5374.71 12 5477.50 13 5624.33 14 6559.11 15 6570.00 16 6577.41 17 6629.00 18 6740.50 表 2 本文设计的模型各网络层具体参数

Table 2 Specific parameters of each network layer in this paper

Layer Detailed parameters Input 256×256,Thermal image Conv1 Number and size of convolution kernels,2

5×5×1Conv2 Number and size of convolution kernels,4

5×5×1Conv3 Number and size of convolution kernels,8

5×5×1Conv4 Number and size of convolution kernels,16

5×5×1Pool Number and size of convolution kernels,1

2×2×1Drop Dropout (0.2) FC 128 fully connected layer Bi-LSTM1 Number of hidden layer nodes 64 Bi-LSTM2 Number of hidden layer nodes 32 Softmax Softmax 表 3 不同批量尺寸识别准确率

Table 3 Different batch size identification accuracy

Batch size Accuracy/% Time/s 16 98.77 261 32 99.87 220 64 100 197 128 94.78 162 表 4 复合检测条件下裂纹尺寸及其标签

Table 4 Crack size and label under composite detection conditions

Serial number Crack length/μm Serial number Crack length/μm a 5374.71 f 7507.79 b 5624.33 g 7930 c 6559.11 h 8414.54 d 6577.41 i 9143 e 7275 j 9453 表 5 Bi-LSTM与其他算法的实验对比

Table 5 Experimental comparison between BI-LSTM and other algorithms

Model Bi-LSTM (This paper) SVM KNN GooLeNet VGG ResNet Accuracy% 100 96.7 99.59 97.8 98.6 99.3 Recognition time/s 197 462 293 309 345 322 -

[1] 韩丽民. 采煤机关键部件故障分析与诊断[J]. 能源与节能, 2021(11): 156-157, 159. DOI: 10.16643/j.cnki.14-1360/td.2021.11.061. HAN limin. Fault analysis and diagnosis of key parts of shearer[J]. Energy and Conservation, 2021(11): 156-157, 159. DOI: 10.16643/j.cnki.14-1360/td.2021.11.061

[2] 窦建. 机电设备维修管理的现状和对策认识实践[J]. 中国设备工程, 2022(13): 79-81. https://www.cnki.com.cn/Article/CJFDTOTAL-SBGL202213036.htm DOU Jian. Current situation and countermeasures of maintenance management of mechanical and electrical equipment[J]. China Equipment Engineering, 2022(13): 79-81. https://www.cnki.com.cn/Article/CJFDTOTAL-SBGL202213036.htm

[3] 冯辅周, 朱俊臻, 闵庆旭, 等. 涡流热像无损检测技术综述[J]. 装甲兵工程学院学报, 2016, 30(6): 60-67. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJBX201606012.htm FENG Fuzhou, ZHU Junzhen, MIN Qingxu, et al. Review of eddy current thermography nondestructive testing[J]. Journal of Academy of Armored Force Engineering, 2016, 30(6): 60-67. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJBX201606012.htm

[4] 苗玲, 高斌, 石永生, 等. 基于电涡流热成像的钢轨滚动接触疲劳裂纹动态检测研究[J]. 机械工程学报, 2021, 57(18): 86-97. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202118011.htm MIAO Ling, GAO Bin, SHI Yongsheng, et al. Dynamic detection of rolling contact fatigue cracks in rail based on eddy current thermal imaging[J]. Journal of Mechanical Engineering, 2021, 57(18): 86-97. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202118011.htm

[5] 毕野, 熊新, 叶波, 等. 基于深度学习的涡流热成像技术在无损检测中的应用[J]. 化工自动化及仪表, 2019, 46(9): 690-696. https://www.cnki.com.cn/Article/CJFDTOTAL-HGZD201909002.htm BI Ye, XIONG Xin, YE Bo, et al. Application of eddy current thermal imaging technology based on deep learning in nondestructive testing[J]. Chemical Automation and Instrumentation, 2019, 46(9): 690-696. https://www.cnki.com.cn/Article/CJFDTOTAL-HGZD201909002.htm

[6] GAO B, LI X, WOO W L, et al. Quantitative validation of eddy current stimulated thermal features on surface crack[J]. Ndt & E International, 2017, 85: 1-12.

[7] 孙吉伟, 孙浩, 谢敏, 等. 涡流脉冲热像技术中基于神经网络的检出/漏检预测研究[J]. 红外技术, 2020, 42(8): 795-800. http://hwjs.nvir.cn/article/id/hwjs202008015 SUN Jiwei, SUN Hao, XIE Min, et al. Prediction of detection detection based on neural network in eddy current pulse thermography[J]. Infrared Technology, 2020, 42(8): 795-800. http://hwjs.nvir.cn/article/id/hwjs202008015

[8] 刘建伟, 宋志妍. 循环神经网络研究综述[J]. 控制与决策, 2022, 37(11): 16. https://www.cnki.com.cn/Article/CJFDTOTAL-KZYC202211001.htm LIU Wei, SONG Zhiyan. Review of recurrent Neural networks[J]. Control and Decision Making, 2022, 37(11): 16. https://www.cnki.com.cn/Article/CJFDTOTAL-KZYC202211001.htm

[9] YU Y, SI X, HU C, et al. A review of recurrent neural networks: LSTM cells and network architectures[J]. Neural Computation, 2019, 31(7): 1235-1270.

[10] Crisóstomo de Castro Filho H, Abílio de Carvalho Júnior O, Ferreira de Carvalho O L, et al. Rice crop detection using LSTM, Bi-LSTM, and machine learning models from sentinel-1 time series[J]. Remote Sensing, 2020, 12(16): 2655.

[11] TIAN G, WANG Q, ZHAO Y, et al. Smart contract classification with a bi-LSTM based approach[J]. IEEE Access, 2020, 8: 43806-43816.

[12] 高玉才, 付忠广, 王诗云, 等. 基于Bi-LSTM和自注意力机制的旋转机械故障诊断方法研究[J]. 中国工程机械学报, 2022, 20(3): 273-278. https://www.cnki.com.cn/Article/CJFDTOTAL-GCHE202203017.htm GAO Yucai, FU Zhongguang, WANG Shiyun. Research on fault diagnosis method of rotating machinery based on BI-LSTM and self-attention mechanism[J]. Chinese Journal of Construction Machinery, 2022, 20(3): 273-278. https://www.cnki.com.cn/Article/CJFDTOTAL-GCHE202203017.htm

[13] 温惠英, 张东冉, 陆思园. GA-LSTM模型在高速公路交通流预测中的应用[J]. 哈尔滨工业大学学报, 2019, 51(9): 81-87, 95. https://www.cnki.com.cn/Article/CJFDTOTAL-HEBX201909012.htm WEN Huiying, ZHANG Dongran, LU Siyuan. Application of GA-LSTM model in expressway traffic flow prediction[J]. Journal of Harbin Institute of Technology, 2019, 51(9): 81-87, 95. https://www.cnki.com.cn/Article/CJFDTOTAL-HEBX201909012.htm

[14] MIN Q, ZHU J, SUN J, et al. Investigation of heat source reconstruction of thickness-through fatigue crack using lock-in vibrothermography[J]. Infrared Physics & Technology, 2018, 94: 291-298.

[15] 林丽, 刘新, 朱俊臻, 等. 基于CNN的金属疲劳裂纹超声红外热像检测与识别方法研究[J]. 红外与激光工程, 2022, 51(3): 475-483. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ202203042.htm LIN Li, LIU Xin, ZU Junzhen, et al. Research on detection and identification of metal fatigue crack by ultrasonic infrared thermography based on CNN[J]. Infrared and Laser Engineering, 2022, 51(3): 475-483. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ202203042.htm

[16] 纪盟盟, 肖金壮, 李瑞鹏. CNN联合BI-LSTM混合模型的手势识别算法[J]. 激光杂志, 2021, 42(6): 88-91. https://www.cnki.com.cn/Article/CJFDTOTAL-JGZZ202106019.htm JI Mengmeng, XIAO Jinzhuang, LI Ruipeng. Gesture recognition algorithm based on CNN combined with BI-LSTM hybrid model[J]. Laser Magazine, 2021, 42(6): 88-91. https://www.cnki.com.cn/Article/CJFDTOTAL-JGZZ202106019.htm

[17] 于洋, 马军, 王晓东, 等. 融合深度可分离小卷积核和CBAM的改进CNN故障诊断模型[J]. 电子测量技术, 2022, 45(6): 171-178. https://www.cnki.com.cn/Article/CJFDTOTAL-DZCL202206027.htm YU Yang, MA Jun, WANG Xiaodong, et al. Improved CNN fault diagnosis model by fusing deep separable small convolution kernel and CBAM[J]. Electronic Measurement Technique, 2022, 45(6): 171-178. https://www.cnki.com.cn/Article/CJFDTOTAL-DZCL202206027.htm

[18] GAO Hongbin, ZHANG Ya, LV Wenkai, et al. A deep convolutional generative adversarial networks-based method for defect detection in small sample industrial parts images[J]. Applied Sciences, 2022, 12(13): 6569.

[19] JIAO J, ZHAO M, LIN J, et al. A multivariate encoder information based convolutional neural network for intelligent fault diagnosis of planetary gearboxes[J]. Knowledge-Based Systems, 2018, 160: 237-250.

[20] 刘杰, 丁武学, 孙宇, 等. 基于SVM的搅拌摩擦焊表面缺陷分类[J]. 组合机床与自动化加工技术, 2022(3): 130-133, 137. https://www.cnki.com.cn/Article/CJFDTOTAL-ZHJC202203031.htm LIU Jie, DING Xuewu, SUN Yu, et al. Surface defect classification of friction stir welding based on SVM[J]. Modular Machine Tools and Automatic Processing Technology. 2022(3): 130-133, 137. https://www.cnki.com.cn/Article/CJFDTOTAL-ZHJC202203031.htm

[21] GUO J, WANG X. Image classification based on SURF and KNN[C]//IEEE/ACIS 18th International Conference on Computer and Information Science (ICIS), 2019: 356-359.

[22] MA J, RAO J, QIAO Y, et al. Sprouting potato recognition based on deep neural network GoogLeNet[C]//IEEE 3rd International Conference on Cloud Computing and Internet of Things (CCIOT), 2018: 502-505.

[23] DUAN C, YIN P, ZHI Y, et al. Image classification of fashion-MNIST data set based on VGG network[C]//Proceedings of 2019 2nd International Conference on Information Science and Electronic Technology (ISET). International Informatization and Engineering Associations: Computer Science and Electronic Technology International Society, 2019: 19.

[24] Mahajan A, Chaudhary S. Categorical image classification based on representational deep network (RESNET)[C]//2019 3rd International conference on Electronics, Communication and Aerospace Technology (ICECA), 2019: 327-330.

-

期刊类型引用(3)

1. 韩文斌. 大型水利工程施工中混凝土大坝活动裂纹检测方法. 水上安全. 2025(01): 103-105 .  百度学术

百度学术

2. 蔡云程. 船用涡流检测技术在船舶结构无损检验中的应用研究. 仪器仪表用户. 2024(06): 101-103+106 .  百度学术

百度学术

3. 曾俊恺. 基于声发射技术的压力容器管道裂纹扩展无损检测方法分析. 中国机械. 2024(31): 126-130 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: