Thermal Integration Analysis of Optical Machines for Axis Alignment Test Systems

-

摘要:

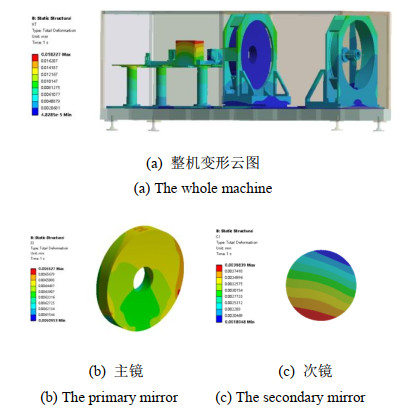

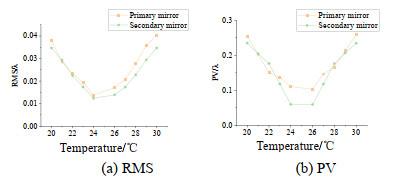

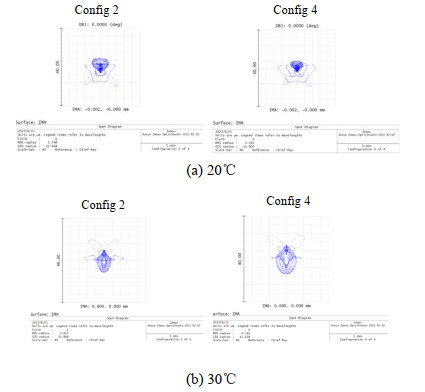

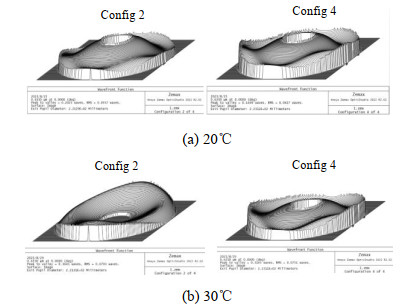

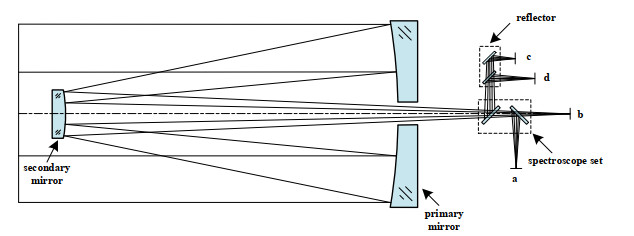

轴对准测试系统是一种应用大口径平行光管法来测量光轴平行性的重要仪器,系统焦距为4800 mm,口径为600 mm。在测试过程中,由于焦距长、口径大,环境温度的变化引起的各元件的微小变形都会影响系统的成像质量及测试精度。因此,需要对该系统进行光机热集成分析。建立了轴对准测试系统的有限元分析模型,分析了稳态温度场、温度梯度场下系统的热变形,利用Zernike多项式对热变形后的镜面进行面型拟合,将拟合系数导入光学设计软件,得到不同温度变化下对轴对准测试系统的影响,通过实验验证了仿真结果的准确性。结果表明:稳态温度场下,在设计参数要求的温度范围内,光学系统波像差均小于λ/10(λ=632.8 nm),光轴平行性检测精度满足0.02 mrad;温度梯度场对系统影响更大,需将系统内外温差控制在±3℃内。

-

关键词:

- 轴对准测试系统 /

- 光机热集成分析 /

- 有限元分析 /

- Zernike多项式 /

- 面型精度

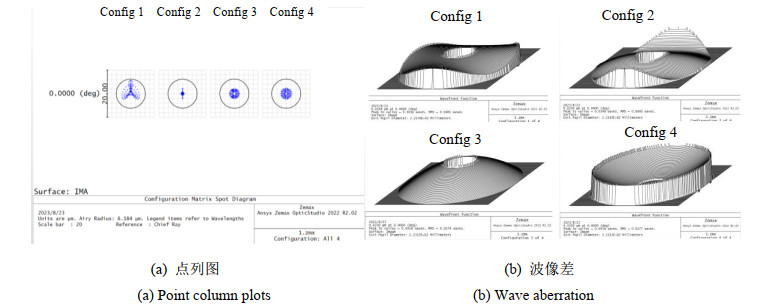

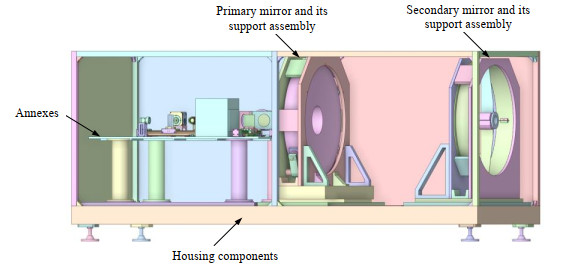

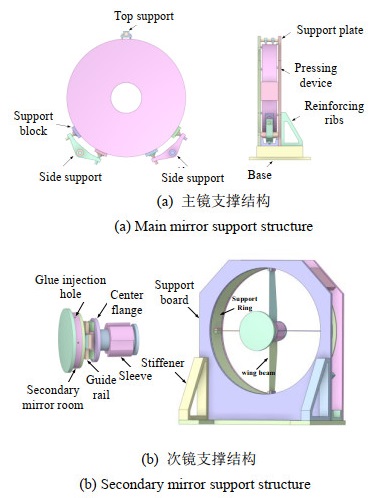

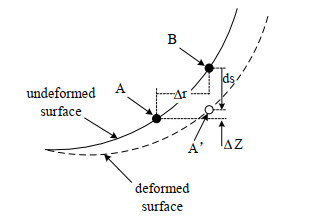

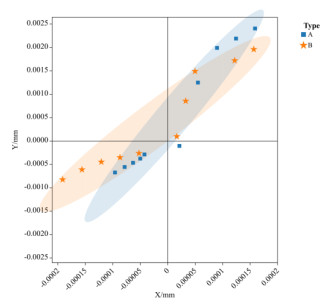

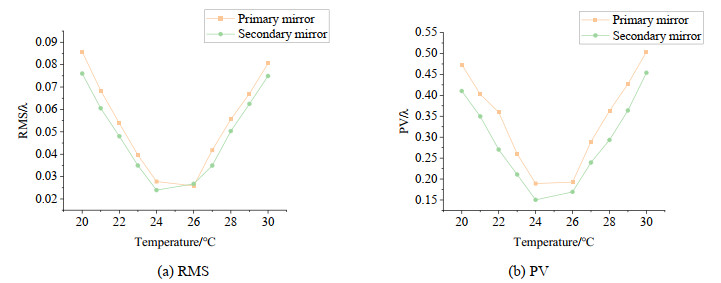

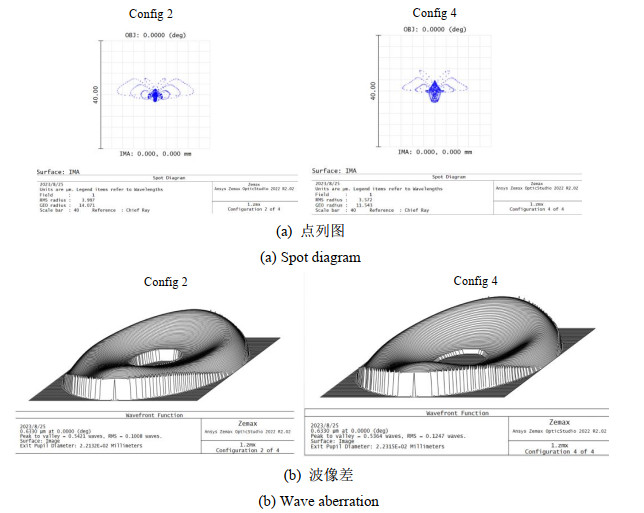

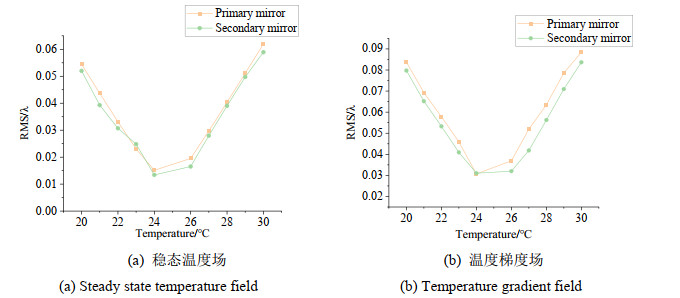

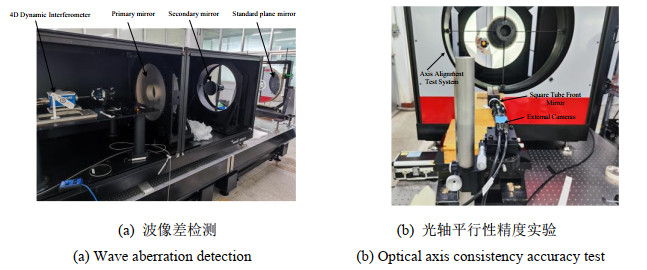

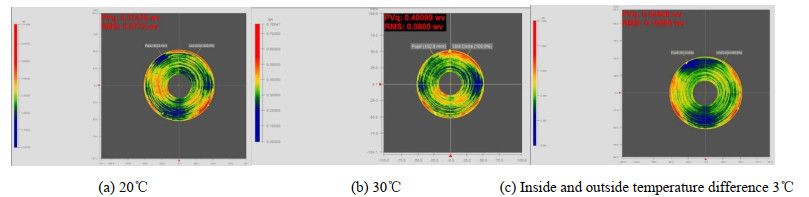

Abstract:The axis alignment test system is an important instrument for measuring the parallelism of optical axes by applying the method of large aperture parallel light tubes, with a focal length of 4800 mm and an aperture of 600 mm. During the test process, due to the long focal length and large aperture, the small deformation of each component caused by the change of the ambient temperature will affect the imaging quality of the system and the test accuracy. Therefore, an opto-mechanical thermal integration analysis of the system is required. The finite element analysis model of the shaft alignment test system was established, the thermal deformation of the system under steady state temperature field and temperature gradient field was analyzed, the Zernike polynomials were used to fit the surface shape of the mirror after thermal deformation, and the fitting coefficients were imported into the optical design software to get the effects on the shaft alignment test system under different temperature changes, and the accuracy of the simulation results was verified by experiments. The results show that: under the steady state temperature field, within the temperature range required by the design parameters, the wave aberration of the optical system is less than λ/10 (λ=632.8 nm), and the accuracy of the optical axis consistency detection meets 0.02mrad; the temperature gradient field has a greater impact on the system, and it is necessary to control the temperature difference between the inside and the outside of the system to within ±3℃.

-

-

表 1 设计参数

Table 1 Design parameters

Technical specifications Numerical values Operating band/μm 0.4~14 Focal length/mm 4800 Aperture/mm 600 Secondary mirror shading ratio 0.34 Surface accuracy of primary and secondary mirrors RMS (root mean square)≤λ/20、PV (peak to valley)≤λ/3(λ=632.8 nm) Wave aberration RMS≤λ/10(λ=632.8 nm) Detector pixel size/μm Visible/NIR:4.8

Short-wave infrared:5

Long-wave infrared:12Operating temperature/℃ 25±5 Optical axis consistency/ mrad 0.02 表 2 各组件材料属性

Table 2 Material properties of each component

Materials Density/(g/cm2) Linear expansion coefficient /℃-1 Elastic modulus /GPa Poisson ratio Microcrystalline glass 2.53 5×10-8 90.3 0.24 F_SILICA 2.2 5×10-7 72.7 0.17 Al6061 2.81 2.34×10-5 70 0.33 45# Steel 7.85 1.16×10-5 210 0.31 Rubber 2.1 1.03×10-4 0.28 0.4 表 3 光轴平行性精度测试

Table 3 Optical axis parallelism accuracy test

Modes Uniform temperature variation Temperature gradient Temperature/℃ 20 30 3 Repeatability accuracy/mrad 0.00363 0.00511 0.00905 Measurement accuracy/% 1.62 1.60 2.76 表 4 光轴平行性检测误差

Table 4 Optical axis parallelism detection accuracy

Modes Uniform temperature variation Temperature gradient Temperature/℃ 20 30 3 Detection accuracy/mrad 0.0073 0.0082 0.011 -

[1] 徐新行, 陈宁, 王兵, 等. 机载紧凑型中波红外相机的设计[J]. 中国激光, 2014, 41(8): 0816002. XU X, CHEN N, WANG B, et al. Design of compact middle-wave infrared camera used on airborne platform[J]. Chinese Journal of Lasers, 2014, 41(8): 0816002.

[2] Miller J, Hatch M, Green K. Predicting performance of optical systems undergoing thermal/mechanical loadings using integrated thermal/structural/optical numerical methods[J]. Optical Engineering, 1981, 20(2): 166-174.

[3] 肖阳, 徐文东, 赵成强. 光机系统的一体化仿真分析[J]. 光学学报, 2016, 36(7): 0722002. XIAO Y, XU W, ZHAO C. Integrated simulation of opto-mechanical system[J]. Acta Optica Sinica, 2016, 36(7): 0722002.

[4] 潘越, 徐熙平, 乔杨. 变焦红外双波段投影镜头的光机热分析[J]. 光学学报, 2018, 38(5): 0522001. PAN Y, XU X, QIAO Y. Optical-structural-thermal analysis of zoom infrared dual-band projection lens[J]. Acta Optica Sinica, 2018, 38(5): 0522001.

[5] YUAN Z, MENG X, LI C, et al. Research on thermal design and thermal optical performance of space telescope based on multidisciplinary integration[J]. Journal of Thermal Stresses, 2022, 45(5): 401-414. DOI: 10.1080/01495739.2022.2049023

[6] 赵源, 张殿富, 王洪伟. 某空间望远镜光机热集成分析[J]. 激光与红外, 2012, 42(4): 404-407. DOI: 10.3969/j.issn.1001-5078.2012.04.011 ZHAO Y, ZHANG D, WANG H. Integrated thermal-structural-optical analysis of a space telescope[J]. Laser & Infrared, 2012, 42(4): 404-407. DOI: 10.3969/j.issn.1001-5078.2012.04.011

[7] 张纪承, 罗海燕, 胡广骁, 等. 空间外差拉曼光谱仪成像镜头光机热集成分析[J]. 应用光学, 2018, 39(3): 332-338. ZHANG Jicheng, LUO Haiyan, HU Guangxiao, et al. Thermal/structural/optical integrated analysis on spatial heterodyne Raman spectrometer imaging lens[J]. Journal of Applied Optics, 2018, 39(3): 332-338.

[8] 刘朋朋, 靳利锋, 赵慧, 等. 低轨道遥感相机光机热一体化分析及优化设计[J]. 红外技术, 2022, 44(6): 614-621. http://hwjs.nvir.cn/article/id/9b4c2bc0-ab24-492c-adc9-bf6120f2a6ad LIU Pengpeng, JIN Lifeng, ZHAO Hui, et al. Integrated opto-mechanical-thermal analysis and optimization design of a low-orbit remote sensing camera[J]. Infrared Technology, 2022, 44(6): 614-621. http://hwjs.nvir.cn/article/id/9b4c2bc0-ab24-492c-adc9-bf6120f2a6ad

[9] 李盛林, 韩光宇, 卢惠琴, 等. 1.25m口径宽波段测试设备设计[J]. 机械设计与制造, 2020(5): 111-115. DOI: 10.3969/j.issn.1001-3997.2020.05.026 LI Shenglin, HAN Guangyu, LU Huiqin, et al. The opto-mechanical structure design of 1.25 meter wide band detection device[J]. Machinery Design & Manufacture, 2020(5): 111-115. DOI: 10.3969/j.issn.1001-3997.2020.05.026

[10] 邵帅. 多波段共口径红外系统光机热一体化设计[J]. 仪器仪表学报, 2013, 34(2): 387-393. DOI: 10.3969/j.issn.0254-3087.2013.02.022 SHAO Shuai. Integrated design of optical-mechanism and heat for shared aperture infrared system with multi-spectrum band[J]. Chinese Journal of Scientific Instrument, 2013, 32(2): 387-393. DOI: 10.3969/j.issn.0254-3087.2013.02.022

[11] 温中凯, 张庆君, 李爽, 等. 空间光电跟瞄系统多光轴平行性标校研究[J]. 中国光学, 2021, 14(3): 625-633. WEN Zhongkai, ZHANG Qingjun, LI Shuang, et al. Multi-optical axis parallelism calibration of space photoelectric tracking and aiming system[J]. Chinese Optics, 2021, 14(3): 625-633.

[12] 金伟其, 王霞, 张其扬, 等. 多光轴一致性检测技术进展及其分析[J]. 红外与激光工程, 2010, 39(3): 526-531. DOI: 10.3969/j.issn.1007-2276.2010.03.031 JIN Weiqi, WANG Xia, ZHANG Qiyang, et al. Technical progress and its analysis in detecting of multi-axes parallelism system[J]. Infrared and Laser Engineering, 2010, 39(3): 526-531. DOI: 10.3969/j.issn.1007-2276.2010.03.031

[13] 杨雪, 陈文红, 张玺, 等. 宽光谱光电系统多光轴平行性工程化测试方法研究[J]. 激光与红外, 2019, 49(8): 978-982. DOI: 10.3969/j.issn.1001-5078.2019.08.012 YANG Xue, CHEN Wenhong, ZHANG Xi, et al. A method for multi-axial parallelism measurement of a multi-band optoelectronic system in engineering[J]. Laser & Infrared, 2019, 49(8): 978-982. DOI: 10.3969/j.issn.1001-5078.2019.08.012

[14] YAN P, LIU K, DUAN J, et al. Switch-zoom optical system design of large aperture ground-based photoelectric detection[C]//8th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Large Mirrors and Telescopes. SPIE, 2016, 9682: 280-288.

[15] 刘家国, 李林. 光机热集成分析中数据转换接口研究[J]. 北京理工大学学报, 2007, 27(5): 427-431. DOI: 10.3969/j.issn.1001-0645.2007.05.012 LIU Jiaguo, LI Lin. Study on the data transfer interface in the thermal/structural/optical integrated analysis[J]. Transactions of Beijing Institute of Technology, 2007, 27(5): 427-431. DOI: 10.3969/j.issn.1001-0645.2007.05.012

[16] Coronato P A, Juergens R C. Transferring FEA results to optics codes with Zernikes: a review of techniques[J]. Optomechanics, 2003, 5176: 1-8.

[17] Keith B Doyle, Victor L Genberg, Gregory J Michels. Integrated Optomechanical Analysis[M]. Second Edition, Bellingham: SPIE Press, 2012. [18] 黄静, 刘朝晖, 折文集, 等. 室内多波段光轴一致性测试系统的设计[J]. 应用光学, 2007, 28(5): 663-666. DOI: 10.3969/j.issn.1002-2082.2007.05.030 HUANG Jing, LIU Zhaohui, SHE Wenji, et al. Design of lab test system for boresight of multi-channel optical axes[J]. Journal of Applied Optics, 2007, 28(5): 663-666. DOI: 10.3969/j.issn.1002-2082.2007.05.030

下载:

下载: