Multi-defect Detection of Welding Surface Based on Eddy Current Pulse Thermography

-

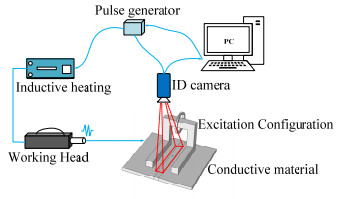

摘要: 焊缝表面气孔缺陷的存在减少了工件的有效截面积,降低了工件抵抗外载荷的能力,严重时会导致工件断裂,为此提出一种基于涡流脉冲热成像技术的焊缝表面多缺陷检测方法。首先,采用一种新型电磁传感器结构,通过涡流脉冲热成像原理对不同直径和深度的碳钢缺陷进行检测,并分析了图像序列中缺陷区域与非缺陷区域的温度信号;为了提高该检测系统的灵敏度,采用主成分分析方法对图像序列进行图像重构,增强原始图像中缺陷特征。最后,通过实验验证了该方法,实验结果表明该方法能够减小焊缝边缘效应的影响,实现对焊缝表面缺陷的大面积检测,并为红外热像仪提供一个开放的视野。Abstract: The existence of porosity defects on the weld surface reduces the effective cross-sectional area of the workpiece and the ability of the workpiece to resist external loads, which leads to workpiece fracture in serious cases. Therefore, a multi-defect detection method for weld surfaces based on eddy current pulse thermography technology is proposed. First, a new electromagnetic sensor structure is adopted to detect carbon steel defects with different diameters and depths through the principle of eddy current pulse thermography, and the temperature signals of the defect and non-defect areas in the image sequence are analyzed. To improve the sensitivity of the detection system, principal component analysis (PCA) is used to reconstruct the image sequence and enhance the defect features in the original image. Finally, the proposed method was verified experimentally. The experimental results show that this method can reduce the influence of the weld edge effect, realize large-area detection of weld surface defects, and provide an open field of vision for infrared thermal imaging.

-

表 1 激励结构参数

Table 1. Dimensions of excitation structure

Parameters L1 L2 L3 L4 L5 L6 L7 Value/mm 100 70 15 15 70 15 15 表 2 圆孔缺陷参数

Table 2. Parameters of round hole defect

Parameters D1 D2 D3 D4 D5 D6 D7 D8 Diameter/mm 4 2 2 2 1 1 1 1 Depth/mm 2 3 2 1 1 2 3 5 -

[1] 沈功田. 承压设备无损检测与评价技术发展现状[J]. 机械工程学报, 2017, 53(12): 1-12. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201712001.htmSHEN Gongtian. Development status of nondestructive testing and evaluation technology for pressure equipment[J]. Journal of Mechanical Engineering, 2017, 53(12): 1-12. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201712001.htm [2] 王强, 胡秋平, 邱金星, 等. 航空复合材料内部缺陷差动式激光红外热成像检测[J]. 红外与激光工程, 2019, 48(5): 127-133. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201905017.htmWANG Qiang, HU Qiuping, QIU Jinxing, et al. Differential laser infrared thermal imaging detection of internal defects in aviation composites[J]. Infrared and Laser Engineering, 2019, 48(5): 127-133. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201905017.htm [3] Broberg P. Surface crack detection in welds using thermogra-phy[J]. NDT & E International, 2013, 57: 69-73. https://www.sciencedirect.com/science/article/pii/S096386951300056X [4] 胡松涛, 石文泽, 卢超, 等. 钢轨踏面裂纹电磁超声表面波同步挤压小波快速成像检测研究[J]. 仪器仪表学报, 2020, 41(1): 35-46. https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB202001004.htmHU Songtao, SHI Wenze, LU Chao, et al. Study on electromagnetic ultrasonic surface wave synchronous extrusion wavelet rapid imaging detection of rail tread crack [J]. Journal of Instrumentation, 2020, 41(1): 35-46. https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB202001004.htm [5] 寇光杰, 杨正伟, 贾庸, 等. 复杂型面叶片裂纹的超声红外热成像检测[J]. 红外与激光工程, 2019, 48(12): 101-109. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201912013.htmKOU Guangjie, YANG Zhengwei, JIA Yong, et al. Detection on cracks in blades with complex profile based on ultrasonic infrared thermal imaging[J]. Infrared and Laser Engineering, 2019, 48(12): 101-109. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201912013.htm [6] 张军, 朱晟桢, 毕贞法, 等. 基于金属磁记忆效应的高铁轮对早期故障检测[J]. 仪器仪表学报, 2018, 39(1): 162-170. https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB201801020.htmZHANG Jun, ZHU Shengzhen, BI Zhenfa, et al. Early fault detection of high-speed rail wheelsets based on metal magnetic memory effect[J]. Journal of Instrumentation, 2018, 39(1): 162-170. https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB201801020.htm [7] YANG Ruizhen, HE Yunze. Logarithmic analysis of eddy current thermo-graphy based on longitudinal heat conduction for subsurface defect evaluation[J]. Infrared Physics & Technology, 2014, 67: 467-472. https://www.sciencedirect.com/science/article/pii/S1350449514001923 [8] 王晓娜, 胡杨, 侯德鑫, 等. 基于方向调制原理的涡流热成像漆层下裂纹检测技术[J]. 仪器仪表学报, 2019, 40(12): 56-63. https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB201912007.htmWANG Xiaona, HU Yang, HOU Dexin, et al. Eddy current thermal imaging under paint crack detection technology based on direction modulation principle[J]. Journal of Instrumentation, 2019, 40(12): 56-63. https://www.cnki.com.cn/Article/CJFDTOTAL-YQXB201912007.htm [9] HE Y, TIAN G Y, PAN M, et al. An investigation into eddy current pulsed thermography for detection of corrosion blister[J]. Corrosion Science, 2014, 78: 1-6. https://www.sciencedirect.com/science/article/pii/S0010938X13004010 [10] XU Changhang, ZHANG Wuyang, WU Changwei, et al. An improved method of eddy current pulsed thermography to detect subsurface defects in glass fiber reinforced polymer composites[J]. Composite Structures, 2020, 242: 112145. [11] YANG Z W, YAN H P, LI Y, et al. A novel inclined excitation method for crack detection of non-ferromagnetic materials using eddy current thermography[J]. Strength of Materials, 2019, 51(4): 558-568. [12] 闫会朋, 杨正伟, 田干, 等. 基于涡流热成像的铁磁材料近面微裂纹检测[J]. 红外与激光工程, 2017, 46(3): 238-243. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201703036.htmYAN Huipeng, YANG Zhengwei, TIAN Gan, et al. Near surface microcrack detection of ferromagnetic materials based on eddy current thermal imaging[J]. Infrared and Laser Engineering, 2017, 46(3): 238-243. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201703036.htm [13] Barakat N, Mortadha J, Khan A, et al. A one-dimensional approach towards edge crack detection and mapping using eddy current thermography[J]. Sensors and Actuators A: Physical, 2020, 309: 111999. [14] Tsopelas N, Siakavellas N J. Experimental evaluation of electromagnetic-thermal non-destructive inspection by eddy current thermography in square aluminum plates[J]. Ndt & E International, 2011, 44(7): 609-620. https://www.sciencedirect.com/science/article/pii/S096386951100079X [15] TIAN Guiyun, GAO Yunlai, LI Kongjing, et al. Eddy current pulsed thermography with different excitation configurations for metallic material and defect characterization[J]. Sensors, 2016, 16(6): 843. https://www.mdpi.com/1424-8220/16/6/843/htm [16] ZHAO Jian, GAO Bin, Woo W L, et al. Crack evaluation based on novel circle-ferrite induction thermography[J]. IEEE Sensors Journal, 2017, 17(17): 5637-5645. [17] LIU Zewei, GAO Bin, TIAN Guiyun. Natural crack diagnosis system based on novel L-shaped electromagnetic sensing thermography[J]. IEEE Transactions on Industrial Electronics, 2019, 67(11): 9703-9714. [18] Hansen K A, Weisberg E C. Asymmetric induction work coil for thermoplastic welding: US, US5444220 A[P]. 1994-12-05 [19] ZHU Z Q, PANG Y, Howe D, et al. Analysis of electromagnetic performance of flux-switching permanent-magnet machines by nonlinear adaptive lumped parameter magnetic circuit model[J]. Transactions on Magnetics, 2005, 41(11): 4277-428. https://ieeexplore.ieee.org/document/1532337 [20] 万李涛, 熊楠菲, 王栋, 等. 信赖域方法在红外图像序列处理中的应用[J]. 红外与激光工程, 2020, 49(7): 258-264. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ202007033.htmWAN Litao, XIONG Nanfei, WANG Dong, et al. Application of trust region method in infrared image sequence processing[J]. Infrared and Laser Engineering, 2020, 49(7): 258-264. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ202007033.htm -

下载:

下载: