Debonding Defect Recognition of Building Decoration Layers by UAV Thermography

-

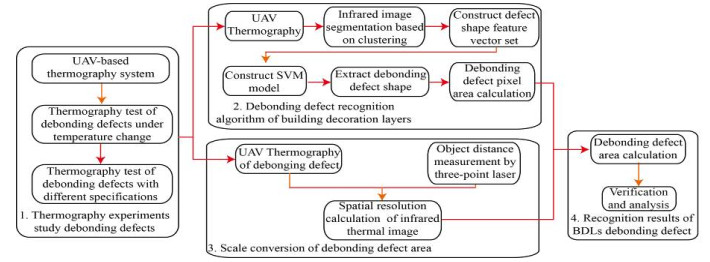

摘要: 建筑外墙饰面层脱粘剥落广泛存在,对居民生命财产安全带来巨大威胁。本文以旋翼无人飞机为工作平台,搭载红外热成像相机对建筑外墙饰面层脱粘缺陷进行成像检测,获得脱粘缺陷热成像温度场分布规律;通过饰面层脱粘缺陷温度场、形状特征分析,提出基于热源聚类的脱粘缺陷红外图像分割方法,构建饰面层脱粘缺陷形状特征向量集,建立基于支持向量机的无人飞机热成像饰面层脱粘缺陷识别特征学习模型、脱粘缺陷实际面积计算方法;以曾出现数次饰面层剥落的教学楼为研究对象,对实际建筑进行无人机机载红外视频成像检测,识别脱粘缺陷面积,并与人工检测进行比较,表明基于先验特征规律提出的脱粘缺陷识别小样本机器学习算法具有优越性,机载热成像识别饰面层脱粘缺陷满足工程精度要求,能有效减少事故发生,具有可行性和广泛应用前景。Abstract: The phenomenon of building decorative layers (BDLs) falling off of exterior walls is quite common, and is of great concerns to human safety. In this study, a rotor unmanned aerial vehicle (UAV) equipped with an infrared thermal camera is used as the working platform to detect debonding BDL defects to obtain the change in law of its thermography imagery. Based on the analysis of the temperature field and shape characteristics of thermography images of BDLs, an image segmentation method for debonding defects based on fuzzy clustering is proposed, and a shape feature vector set of debonding BDL defects is constructed. Therefore, a feature learning model for debonding defect recognition and a calculation method for the actual area of debonding defects based on support vector machines are established. Finally, a case study of the teaching building inspection with several peeling veneers is carried out to demonstrate the effectiveness of the proposed method. Compared with the manual test, the results show that the small-sample machine-learning algorithm for debonding defect recognition based on prior feature law has advantages, and can effectively reduce the occurrence of accidents presenting potential practical applications.

-

表 1 脱粘缺陷区域形状特征参数计算

Table 1. Calculation of shape characteristic parameters of debonding defect area

Item Area (1) Area (2) Area/pixel 3233 1685 Rectangularity 0.83 0.29 Elongation 0.82 0.69 Circularity 0.76 0.19 Circumference /pixel 725 382 Eccentricity 0.26 0.91 Minimum bounding rectangle 0.97 0.52 表 2 机载热成像饰面缺陷面积识别与比对

Table 2. Recognition and comparison of debonding defects based on UAV thermography imagery

Item Area Ι Area Ⅱ Area Ⅲ Object distance/m 5.388 4.018 4.864 Pixel resolution/(mm/pixel) 8.99 6.83 8.27 Pixels 5024 6287 4569 Area/m2 0.406 0.293 0.312 Artificial detection width/m2 0.400 0.304 0.336 Accuracy/% 98.5 96.4 92.8 -

[1] 冯力强, 王欢祥, 晏大伟, 等. 建筑外墙饰面层内部缺陷红外热像法检测试验研究[J]. 土木建筑与环境工程, 2014, 36(2): 57-61 https://www.cnki.com.cn/Article/CJFDTOTAL-JIAN201402009.htmFENG Liqiang, WANG Huanxiang, YAN Dawei, et al. Experimental study on inside defects of building exterior wall decoration layer by infrared thermal imaging method[J]. Journal of Chongqing Jianzhu University, 2014, 36(2): 57-61. https://www.cnki.com.cn/Article/CJFDTOTAL-JIAN201402009.htm [2] 朱红光, 易成, 胡玉琨, 等. 红外热像诊断外墙饰面层粘结缺陷的检测条件研究[J]. 建筑技术, 2016, 47(2): 172-175. doi: 10.3969/j.issn.1000-4726.2016.02.024ZHU Hongguang, YI Cheng, HU Yukun, et al. Study on detection conditions for infrared thermography diagnosis of debonding defect of exterior wall decoration layer[J]. Building Technology, 2016, 47(2): 172-175. doi: 10.3969/j.issn.1000-4726.2016.02.024 [3] 朱雷, 房志明, 王卓琳, 等. 外墙饰面层粘结缺陷的检测评估[J]. 无损检测, 2016, 38(6): 10-16. https://www.cnki.com.cn/Article/CJFDTOTAL-WSJC201606004.htmZHU Lei, FANG Zhiming, WANG Zhuolin, et al. Detection and evaluation of debonding defect of exterior wall decoration layer[J]. Nondestructive Testing, 2016, 38(6): 10-16. https://www.cnki.com.cn/Article/CJFDTOTAL-WSJC201606004.htm [4] 冯力强, 王欢祥, 晏大玮, 等. 红外热像法检测建筑外墙饰面层内部缺陷试验研究[J]. 土木工程学报, 2014, 47(6): 51-56. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201406010.htmFENG Liqiang, WANG Huanxiang, YAN Dawei, et al. Experimental study on internal defects detection of exterior wall finish coat by infrared thermography[J]. China Civil Engineering Journal, 2014, 47(6): 51-56. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201406010.htm [5] Gene S, Hojjat A. Infrared thermography for detecting defects in concrete structures[J]. Journal of Civil Engineering and Management, 2018, 24: 508-515. doi: 10.3846/jcem.2018.6186 [6] WANG L, ZHANG Z. Automatic detection of wind turbine blade surface cracks based on UAV-taken images[J]. IEEE Transactions on Industrial Electronics, 2017, 64(9): 7293-7303. doi: 10.1109/TIE.2017.2682037 [7] CHEN S, Laefer D F, Mangina E, et al. UAV bridge inspection through evaluated 3D reconstructions[J]. Journal of Bridge Engineering, 2019, 24(4): 05019001. doi: 10.1061/(ASCE)BE.1943-5592.0001343 [8] CHEN S, Laefer D F, Mangina E. State of technology review of civilian UAVs[J]. Recent Patents on Engineering, 2016, 10(3): 160-174. doi: 10.2174/1872212110666160712230039 [9] Rakha T, Gorodetsky A. Review of unmanned aerial system (UAS) applications in the built environment: towards automated building inspection procedures using drones[J]. Automation in Construction, 2018, 93: 252-264. doi: 10.1016/j.autcon.2018.05.002 [10] Sattar D, Thomas R J, Marc M. Fatigue Crack Detection using unmanned aerial systems in fracture critical inspection of steel bridges[J]. Journal of Bridge Engineering, 2018, 23(10): 04018078. doi: 10.1061/(ASCE)BE.1943-5592.0001291 [11] Tarek O, Nehdi M L. Remote sensing of concrete bridge decks using unmanned aerial vehicle infrared thermography[J]. Automation in Construction, 2017, 83: 360-371. doi: 10.1016/j.autcon.2017.06.024 [12] Patel D, Estevam Schmiedt J, Röger M, et al. Approach for external measurements of the heat transfer coefficient (U-value) of building envelope components using UAV based infrared thermography [C]//14th Quantitative Infrared Thermography Conference, 2018: 379-386. [13] A Ellenberg, A Kontsos, F Moon, I Bartoli. Bridge deck delamination identification from unmanned aerial vehicle infrared thermography, automation in construction[J]. Automation in Construction, 2016, 72: 155-165 doi: 10.1016/j.autcon.2016.08.024 [14] Dusik K, Youn J. Automatic photovoltaic panel area extraction from UAV thermal infrared images[J]. Journal of the Korean Society of Surveying Geodesy Photogrammetry and Cartography, 2016, 34(6): 559-568. doi: 10.7848/ksgpc.2016.34.6.559 [15] 勾红叶, 杨彪, 华辉, 等. 桥梁信息化及智能桥梁2019年度研究进展[J]. 土木与环境工程学报, 2020, 42(5): 14-27. https://www.cnki.com.cn/Article/CJFDTOTAL-JIAN202005002.htmGOU Hongye, YANG Biao, HUA Hui, et al. Research progress of bridge informatization and intelligent bridge in 2019[J]. Journal of Civil and Environmental Engineering, 2020, 42(5): 14-27. https://www.cnki.com.cn/Article/CJFDTOTAL-JIAN202005002.htm [16] 鲍跃全, 李惠. 人工智能时代的土木工程[J]. 土木工程学报, 2019, 52(5): 5-15.BAO Yuequan, LI Hui. Artificial intelligence for civil engineering[J]. China Civil Engineering Journal, 2019, 52(5): 5-15. [17] Janssens O, Walle R V D, Loccufier M. Deep learning for infrared thermal image based machine health monitoring[J]. IEEE/ASME Transactions on Mechatronics, 2018, 23(1): 151-159. doi: 10.1109/TMECH.2017.2722479 [18] GONG X, YAO Q, WANG M, et al. A deep learning approach for oriented electrical equipment detection in thermal images[J]. IEEE ACCESS, 2018(6): 41590-41597. http://www.onacademic.com/detail/journal_1000040459031010_dcc9.html [19] ZHANG X, LI C, MENG Q, et al. Infrared image super resolution by combining compressive sensing and deep learning[J]. Sensors, 2018, 18(8): 2587. doi: 10.3390/s18082587 [20] LUO Q, GAO B, Woo W L, et al. Temporal and spatial deep learning network for infrared thermal defect detection[J]. NDT & E International, 2019, 108: 102164. http://www.sciencedirect.com/science/article/pii/S0963869519301355 [21] N Saeed, N King, Z Said, et al. Automatic defects detection in CFRP thermograms, using convolutional neural networks and transfer learning[J]. Infrared Physics & Technology, 2019, 102: 03048. http://www.sciencedirect.com/science/article/pii/S1350449519303135 [22] 钟新谷, 彭雄, 沈明燕. 基于无人飞机成像的桥梁裂缝宽度识别可行性研究[J]. 土木工程学报, 2019, 52(4): 52-61. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201904005.htmZHONG Xingu, PENG Xiong, SHEN Mingyan. Study on the feasibility of identifying bridge crack width with images acquired by unmanned aerial vehicles[J]. China Civil Engineering Journal, 2019, 52(4): 52-61. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201904005.htm [23] 钟新谷, 彭雄. 基于无人飞机机载成像的混凝土裂缝宽度识别方法: 0845685.9, 中国[P]. 2019-02-19.ZHONG Xingu, PENG Xiong. Concrete-crack-width identification system and method based on robot bomb airborne imaging: 0845685.9 China, [P]. 2019-02-19 [24] CHEN L C, Papandreou G, Kokkinos I, et al. Semantic image segmentation with deep convolutional nets and fully connected CRFs[J]. Computer Science, 2014(4): 357-361. http://arxiv.org/pdf/1412.7062 [25] 王晓飞, 胡凡奎, 黄硕. 基于分布信息直觉模糊c均值聚类的红外图像分割算法[J]. 通信学报, 2020, 41(5): 120-129. https://www.cnki.com.cn/Article/CJFDTOTAL-TXXB202005013.htmWANG Xiaofei, HU Fankui, HUANG Shuo, Infrared image segmentation algorithm based on distribution information intuitionistic fuzzy c-means clustering[J]. Journal on Communications, 2020, 41(5): 120-129. https://www.cnki.com.cn/Article/CJFDTOTAL-TXXB202005013.htm [26] 李可心, 王钧, 戚大伟. 基于G-S-G的混凝土结构裂缝识别及监测方法[J]. 振动与冲击, 2020, 39(11): 101-108. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202011013.htmLI Kexin, WANG Jun, QI Dawei. Research on crack identification and monitoring method of concrete structure based on G-S-G[J]. Journal of Vibration and Shock, 2020, 39(11): 101-108. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202011013.htm [27] 王睿, 漆泰岳. 基于机器视觉检测的裂缝特征研究[J]. 土木工程学报, 2016, 49(7): 123-128 https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201607012.htmWANG Rui, QI Taiyue. Study on crack characteristics based on machine vision detection[J]. China Civil Engineering Journal, 2016, 49(7): 123-128. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201607012.htm [28] HWANG Soonkyu, AN Yun Kyu, KIM Ji Min, et al. Monitoring and instantaneous evaluation of fatigue crack using integrated passive and active laser thermography[J]. Optics and Lasers in Engineering, 2019, 119: 9-17. doi: 10.1016/j.optlaseng.2019.02.001 [29] Kang D, Benipal S S, Gopal D L, et al. Hybrid pixel-level concrete crack segmentation and quantification across complex backgrounds using deep learning[J]. Automation in Construction, 2020, 118: 103291. doi: 10.1016/j.autcon.2020.103291 [30] CHEN L C, Papandreou G, Kokkinos I, et al. DeepLab: semantic image segmentation with deep convolutional nets, atrous convolution, and fully connected CRFs[J]. IEEE Transactions on Pattern Analysis & Machine Intelligence, 2016, 40(4): 834-848. http://cseweb.ucsd.edu/classes/sp17/cse252C-a/CSE252C_20170501.pdf -

下载:

下载: