Design, Preparation and Characterization of Infrared Low-Emissivity Film

-

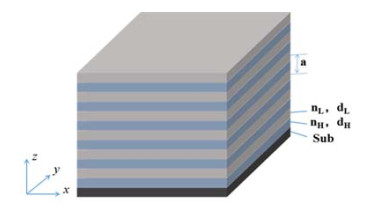

摘要: 为了降低红外探测技术对军事目标生存能力的威胁,研制了红外低辐射膜。设计并制备了基于一维光子晶体结构的红外低辐射膜,通过结构参数优化,改善了其红外波段反射性能,并降低了薄膜总厚度。采用红外椭偏仪测试了原材料Ge膜和ZnS膜的厚度和折射率,将测试结果带入设计结构,制备了8~12 μm发射率分别为0.045、0.097、0.174和0.346的红外低辐射膜。研究结果表明,通过结构优化,可制备出不同发射率的红外低辐射膜,满足武器装备不同辐射背景下的红外隐身要求。Abstract: Military targets require infrared (IR) stealth performance because of the rapid development of IR detection technology. In this study, an IR low-emissivity film based on a one-dimensional photonic crystal structure was designed and fabricated. The IR reflectance of the low-emissivity film was improved, and the total thickness of the film was reduced by optimizing its construction parameters. The thickness and optical parameters of the Ge and ZnS film prepared via vacuum evaporation were tested using an IR ellipsometer. The IR low-emissivity films with IR emissivities of 0.045, 0.097, 0.174, and 0.346 were prepared via vacuum evaporation after the optimized test results were incorporated into the crystal structure design. The IR reflectivity of the IR low-emissivity films was measured using a Fourier-transform IR spectrometer. The test results agreed well with the calculated results.

-

表 1 不同厚度的红外低辐射膜的理论红外性能

Table 1. Theoretical infrared performance of infrared low-emissivity film with different thickness

Number of layers Total thickness /μm 8-14 μm theoretical average reflectivity Relative value of thickness reduction Relative value of theoretical average reflectivity reduction 16 15.9 98.7% 25.4% 0.9% 13 11.35 98.1% 46.7% 1.5% 7 6.98 90.9% 67.2% 8.7% 3 2.41 82.4% 88.7% 17.3% 1 0.63 67.4% 97.0% 32.3% 表 2 制备的Ge膜和ZnS膜停镀点和tooling值

Table 2. Stop coating point and tooling value of prepared Ge film and ZnS film

Material Equipment input thickness/kA Stop coating thickness/kA Test thickness/kA Thickness difference/% Tooling value Ge 5.000 5.013 5.164 3.01 1.030 ZnS 9.000 9.027 7.854 12.99 0.870 表 3 8~14 μm理论与实测平均反射率对比表

Table 3. Comparison of 8-14 μm theoretical and measured average reflectivity

Number of layers Total thickness/μm Theoretical average reflectivity Measured average reflectivity Average reflectivity difference 24 21.4 99.6% 98.2% -1.4% 7 6.98 90.9% 89.3% -1.6% 3 2.41 82.4% 80.1% -2.3% 1 0.63 67.4% 68.7% -1.3% 表 4 在8~12 μm波段理论设计结果、反射光谱测试结果和发射率测试结果对比表

Table 4. Comparison between theoretical design results, reflection spectrum test results and emissivity test results in 8-12 μm

Number of layers Total thickness/μm Design average reflectivity Test average reflectivity Theoretical emissivity Measured emissivity Difference between theoretical and measured emissivity 24 21.4 99.7% 98.2% 0.018 0.045 0.027 7 6.98 90.5% 91.2% 0.088 0.097 0.009 3 2.41 84.7% 83.9% 0.161 0.174 0.013 1 0.63 68.1% 68.7% 0.313 0.346 0.033 -

[1] 钱昂, 何友金, 刘亮. 反舰导弹中波与长波红外成像制导优势对比研究[J]. 红外技术, 2014, 36(8): 671-675. http://hwjs.nvir.cn/article/id/3c59e358-47c5-4df4-b024-9e1ecf6ebd51QIAN Ang, HE Youjin, LIU Liang. A comparative study of the advantage of infrared imaging guidance anti-ship missiles based on medium wave and long-wave[J]. Infrared Technology, 2014, 36(8): 671-675. http://hwjs.nvir.cn/article/id/3c59e358-47c5-4df4-b024-9e1ecf6ebd51 [2] 赵峰民, 刘皞, 陈望达. 微波/红外成像复合制导技术发展分析[J]. 激光与红外, 2012, 42(1): 8-10. doi: 10.3969/j.issn.1001-5078.2012.01.002ZHAO Fengmin, LIU Hao, CHEN Wangda. Analysis of the development of radar/IR compound guidance technique[J]. Laser & Infrared, 2012, 42(1): 8-10. doi: 10.3969/j.issn.1001-5078.2012.01.002 [3] 吴涛, 白云塔. 激光/红外复合制导技术研究综述[J]. 红外, 2008, 29(9): 6-8. doi: 10.3969/j.issn.1672-8785.2008.09.002WU Tao, BAI Yunta. Overview of research on laser/infrared compound guidance techniques[J]. Infrared(Monthly), 2008, 29(9): 6-8. doi: 10.3969/j.issn.1672-8785.2008.09.002 [4] 李永波, 朱洪利, 张宝芹, 等. 隐身涂料研究现状及发展趋势[J]. 材料导报, 2015, 29(26): 358-360. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2015S2086.htmLI Yongbo, ZHU Hongli, ZHANG Baoqin, et al. Research status and development trend of stealth coating[J]. Materials Reports, 2015, 29(26): 358-360. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2015S2086.htm [5] 王子君. 基于冷屏和隐身薄膜的热源目标红外隐身研究[D]. 合肥: 中国科技大学, 2018: 2-11.WANG Zijun. Infrared Stealth of Heat Source Target based on Cold Plate and Stealth Film[D]. Hefei: University of Science and Technology of China, 2018: 2-11. [6] QI Dong, WANG Xian, CHENG Yongzhi, et al. Design and charac- terization of one-dimensional photonic crystals based on Zns/Ge for infrared-visible compatible stealth applications[J]. Optical Materials, 2016, 62: 52-56. doi: 10.1016/j.optmat.2016.09.024 [7] 杜宏艳, 戚宇帆, 吴晨雪, 等. SiO2光子晶体结构色薄膜的制备与光学性能研究[J]. 材料工程, 2019, 47(12): 111-117. doi: 10.11868/j.issn.1001-4381.2018.001044DU Hongyan, QI Yufan, WU Chenxue, et al. Preparation and optical properties of SiO2 photonic crystal structured color films[J]. Journal of Materials Engineering, 2019, 47(12): 111-117. doi: 10.11868/j.issn.1001-4381.2018.001044 [8] 王志迅. 一维光子晶体在红外隐身材料应用方面的设计与实现[D]. 武汉: 华中科技大学, 2015: 38-47.WANG Zhixun. Design and Implementation of One-Dimensional Photonic Crystal in Infrared Stealth Materials[D]. Wuhan: Huazhong University of Science and Technology, 2015: 38-47. [9] 卢仪, 卜小海, 李栋先, 等. 基于光子晶体的红外隐身材料研究进展[J]. 激光与光电子学进展, 2019, 56(8): 080003-1-9. https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201908003.htmLU Yi, BU Xiaomei, LI Dongxian, et al. Research progress of infrared stealth materials based on photonic crystals[J]. Laser & Optoelectronics Progress, 2019, 56(8): 080003-1-9. https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201908003.htm [10] 李康文, 李享成, 陈平安, 等. 基于异质结构的一维光子晶体红外3~5μm高反射镜设计[J]. 光学学报, 2018, 38(9): 092201-1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-GXXB201809040.htmLI Kangwen, LI Xiangcheng, CHEN Pingan, et. al. Design of one-dimensional photonic crystal high mirror based on heterostructure at 3~5μm[J]. Acta Optica Sinica, 2018, 38(9): 092201-1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-GXXB201809040.htm [11] 林伟丽, 邱桂花, 于名讯, 等. 一维光子晶体兼容隐身材料研究进展[J]. 兵器材料科学与工程, 2017, 40(6): 114-118. https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201706032.htmLIN Weili, QIU Guihua, YU Mingxun, et al. Research progress of one-dimensional photonic crystal compatible stealth materials[J]. Ordnance Material Science and Engineering, 2017, 40(6): 114-118. https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201706032.htm [12] 付伟. 红外隐身原理及应用技术[J]. 红外与激光工程, 2002, 31(1): 88-92. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ200201020.htmFU Wei. Principle and application technology of IR stealth[J]. Infrared and Laser Engineering, 2002, 31(1): 88-92. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ200201020.htm [13] 谢民勇, 沈卫东, 宋斯洪, 等. 基于目标与背景红外辐射对比度的红外隐身效能研究[J]. 红外技术, 2011, 33(2): 113-115. doi: 10.3969/j.issn.1001-8891.2011.02.011XIE Minyong, SHEN Weidong, SONG Sihong, et al. Effectiveness evaluation of infrared stealth based on the constant of target and background infrared radiation[J]. Infrared Technology, 2011, 33(2): 113-115. doi: 10.3969/j.issn.1001-8891.2011.02.011 -

下载:

下载: