Effect of in-Situ Post-annealing on the Second Phase Inclusion Defects

-

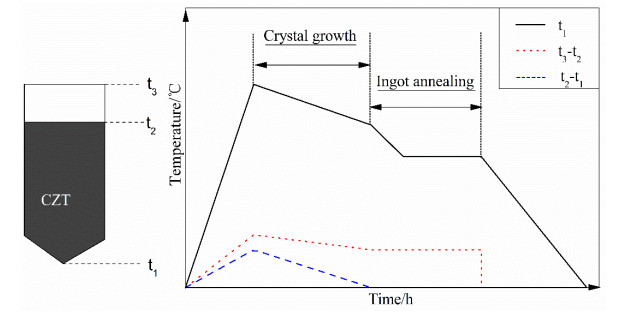

摘要: 采用传统布里奇曼法生长碲锌镉晶体,在配料过程中添加适当过量的Cd,并在晶体生长结束阶段的降温过程中加入晶锭原位退火工艺,晶体的第二相夹杂缺陷得到了有效抑制。根据晶体第二相夹杂缺陷的形成机理,结合热扩散理论和碲锌镉晶体的P-T相图,研究了退火温度对晶体第二相夹杂缺陷密度和粒度(尺寸)的影响,获得了抑制碲锌镉晶体第二相夹杂缺陷的退火条件。利用优化的退火条件制备碲锌镉晶体,晶体第二相夹杂缺陷的尺寸小于10 μm,密度小于250 cm-2。Abstract: Second-phase-inclusion defects in Bridgman-grown CdZnTe crystals were decreased via post-growth in-situ annealing combined with excess Cd in CdZnTe ingots. Based on the formation mechanism of the second-phase-inclusion defects in Bridgman-grown CdZnTe, the relationship between second-phase-inclusion defects and annealing temperature was studied. The size of second-phase-inclusion defects was reduced to less than 10 μm and their density to less than 250 cm-2 in CdZnTe at an optimized in-situ post-annealing temperature.

-

Key words:

- CdZnTe /

- second phase inclusion defects /

- in-situpost-annealing

-

图 3 不同组分碲锌镉晶体的P-T相图[8]:1. CdTe;2. Cd0.95Zn0.05Te;3. Cd0.85Zn0.15Te;4. Cd0.5Zn0.5Te;5. Cd0.2Zn0.8Te;6. Cd0.1Zn0.9Te;7. ZnTe;8. Ref[13];9. Ref[13];10. Ref[14]

Figure 3. P-T phase diagram of CdZnTe[8]: 1. CdTe; 2. Cd0.95Zn0.05Te; 3. Cd0.85Zn0.15Te; 4. Cd0.5Zn0.5Te; 5. Cd0.2Zn0.8Te; 6. Cd0.1Zn0.9Te; 7. ZnTe; 8. Ref[13]. 9. Ref[13]; 10. Ref[14]

图 9 两种工艺条件下生长晶体的形貌和EPD情况:(a) 常规(未含退火工艺)生长的碲锌镉晶体形貌;(b) 含退火工艺生长的碲锌镉晶体形貌;(c) 常规(未含退火工艺)生长的晶体典型(图 10中的第6批次)EPD~3×104 cm-2,(d) 含退火工艺生长的碲锌镉晶体典型(图 10中的第6批次)EPD~2.2×104 cm-2

Figure 9. 10 lots of run-to-run X-ray diffraction image and EPD results of CdZnTe with/without in-situ post-annealing, CdZnTe without post-annealing process(a)(c), CdZnTe with post-annealing process(b)(d)

-

[1] Kinch M A. HgCdTe: recent trends in the ultimate IR semiconductor[J]. J. Electron. Mater. , 2010, 39(7): 1043-1052. doi: 10.1007/s11664-010-1087-6 [2] Chang Y, Becker C R, Grein C H, et al. Surface morphology and defect formation mechanisms for HgCdTe (211)B grown by molecular beam epitaxy[J]. Journal of Electronic Materials, 2008, 37: 1171-1183. doi: 10.1007/s11664-008-0477-5 [3] 张阳, 吴军, 木胜, 等. CdZnTe中富碲沉积相缺陷引起的液相外延HgCdTe薄膜表面缺陷[J]. 红外与毫米波学报, 2018, 37(6): 728-733. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYH201806016.htmZHANG Yang, WU Jun, MU Sheng, et al. Surface defects of liquid phase epitaxial growth of HgCdTe film induced by Te-rich precipitates in CdZnTe substrates[J]. J. Infrared Millim. Waves, 2018, 37(6): 728-733. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYH201806016.htm [4] Belas E, Bugár M, Grill R, et al. Elimination of inclusions in (CdZn) Te substrates by post-grown annealing[J]. J. Electron. Mater., 2007, 36: 1025-1030. doi: 10.1007/s11664-007-0167-8 [5] Kim K, Hwang S, Yu H, et al. Two-step annealing to remove Te secondary-phase defects in CdZnTe while preserving the high electrical resistivity[J]. IEEE Transactions on Nuclear Science, 2018, 65(8): 2333-2337. doi: 10.1109/TNS.2018.2856805 [6] SHENG F F, YANG J R, SUN S W, et al. Influence of Cd-rich annealing on defects in Te-rich CdZnTe materials[J]. J. Electron. Mater. , 2014, 43(7): 2702-2708. doi: 10.1007/s11664-014-3140-3 [7] Zanio Kenneth. Chemical Diffusion in Cadmium Telluride[J]. Journal of Applied Physics, 1970, 41(5): 1935-1940. doi: 10.1063/1.1659145 [8] Everson W J, Ard C K, Sepich J L, et al. Etch pit characterization of CdTe and CdZnTe substrates for use in mercury cadmium telluride epitaxy[J]. Journal of Electronic Materials, 1995, 24: 505-510. doi: 10.1007/BF02657954 [9] ZHANG N, Yeckel A, Burger A, et al. Anomalous segregation during electrodynamic gradient freeze growth of cadmium zinc telluride[J]. Journal of Crystal Growth, 2011, 325(1): 10-19. doi: 10.1016/j.jcrysgro.2011.04.041 [10] Roy U N, Weiler S, Stein J. Growth and interface study of 2 in diameter CdZnTe by THM technique[J]. J. Cryst. Growth, 2010, 312(19): 2840-2845. doi: 10.1016/j.jcrysgro.2010.05.046 [11] SHEN J, Aidun D K, Regel L, et al. Characterization of precipitates in CdTe and Cd1-xZnxTe grown by vertical Bridgman-Stock barger technique[J]. Journal of Crystal Growth, 1993, 132(1-2): 250-260. doi: 10.1016/0022-0248(93)90269-3 [12] Zanio K. Chemical diffusion in Cadmium Telluride[J]. J. Appl. Phys. , 1970, 41(5): 1935-1940. doi: 10.1063/1.1659145 [13] Jordan A S, Zupp R P. Calculation of the P-T diagrams of CdTe[J]. J. Electrochem. Soc., 1969, 116(9): 1264-1285. doi: 10.1149/1.2412294 [14] Lorenz M R. Phase equilibria in the system Cd-Te[J]. Journal of Physics and Chemistry of Solids, 23(7): 939-947. -

下载:

下载: